Exploring Waste Heat Recovery Units

Waste heat recovery units (WHRUs) are pivotal in modern energy efficiency efforts, capturing unused heat from various sources and converting it into usable energy. These systems are integral to operations ranging from industrial processes to power generation, significantly impacting energy conservation and operational efficiency.

Types and Applications of WHRUs

Waste heat recovery unit gas turbines are commonly employed in power plants and industrial settings, harnessing exhaust heat to generate additional electricity. Similarly, waste heat recovery equipment is utilized across multiple sectors, including manufacturing and maritime, with waste heat recovery unit offshore installations playing a crucial role in reducing energy consumption on oil platforms.

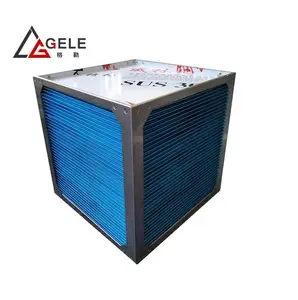

Features and Materials

WHRUs are designed with a focus on durability and performance. The construction typically involves robust materials capable of withstanding high temperatures and corrosive environments. Advanced units may include features such as automated cleaning systems to maintain efficiency and prolong the lifespan of the equipment.

Advantages of Implementing WHRUs

The adoption of a heat recovery unit waste system offers numerous benefits. These units can significantly reduce energy costs by reclaiming heat that would otherwise be lost. Moreover, they contribute to environmental sustainability by lowering greenhouse gas emissions, aligning with global efforts to combat climate change.

Considerations for Selection

Selecting the appropriate WHRU involves considering processing capacity, which can range from as little as 0.5m³/h to over 1000m³/h, ensuring the unit meets the specific needs of the application. Prospective users should evaluate the unit's compatibility with their existing systems and the space available for installation.

Integration and Operation

WHRUs are engineered for ease of integration into existing systems. With pre-assembled components, such as water pumps and internal pipelines, setup is streamlined. Operators will need to assess their site conditions to determine the optimal water inlet configuration, ensuring efficient operation of the unit.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4