Vacuum forming machines are devices used in the manufacturing industry to shape plastic sheets into various three-dimensional forms or molds. This thermoforming process involves heating a plastic sheet until it becomes pliable. Once done, place the plastic sheet over a mold, and use a vacuum to draw the heated plastic tightly against the mold's surface. This creates the desired shape as the plastic cools and solidifies.

Main components of a vacuum forming machine

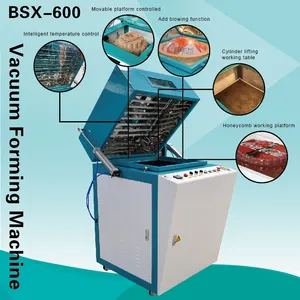

The heating element or oven in the plastic vacuum forming machine plays a pivotal role in the thermoforming process. It heats the plastic sheet to a specific temperature, usually just below its melting point, making it pliable and easily moldable. The controlled heating process ensures uniform softening of the plastic sheet for consistent forming across the entire surface. The frame or platform that holds the mold serves as the base for the forming process. It secures the mold in place and provides stability for the plastic sheet during forming. The molds are typically made from aluminum, wood, or composite materials. They are custom-designed to replicate the desired shape or pattern for the final plastic product.

The vacuum system is a crucial component that removes air from between the softened plastic sheet and the mold. This process creates atmospheric pressure, forcing the pliable plastic to conform precisely to the contours of the mold, capturing its shape and details. A strong vacuum ensures an even and accurate forming process, resulting in high-quality finished products. In addition to these primary components, some advanced vacuum-forming machines incorporate cutting tools or trimming mechanisms. These tools enable precise cutting or trimming of excess plastic from the formed parts or sheets, streamlining the production process and ensuring clean and accurate final products without the need for secondary trimming or finishing procedures.

Diverse options for vacuum forming machines

Vacuum forming machines come in a variety of options tailored to different manufacturing needs and scales of production. Desktop vacuum forming machines are compact units designed for prototyping, small-scale production, or hobbyist use. These small vacuum forming machines offer convenience and affordability for creating prototypes, personalized items, or small batches of plastic components. Table top vacuum forming machines are suitable for workshops, small businesses, or enthusiasts looking to experiment with thermoforming processes.

On the other end of the spectrum, large vacuum forming machines cater to industrial-scale production needs. These industrial vacuum forming machines are equipped with larger work areas, robust heating elements, and powerful vacuum systems to handle larger sheets of plastic and produce a higher volume of formed parts. They are commonly found in manufacturing facilities, automotive plants, or industries requiring mass production of plastic components. Additionally, thermo vacuum forming machines specialize in working with specific types of thermoplastics, offering precise temperature control and compatibility with various plastic materials, making them suitable for specific manufacturing applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4