Rubber tyre recycling is a critical process that transforms end-of-life tires into reusable materials. The procedure involves collecting and treating these tires to recover valuable components, thereby preventing the accumulation of tire waste in landfills. The EU’s definition of recycling excludes energy recovery or backfilling uses, focusing instead on creating products or materials from waste.

The recycling of car tires can be achieved through methods such as grinding and devulcanisation. Grinding involves several steps, including the separation of steel rims and textile cords, followed by the grinding of scrap rubber at ambient or cryogenic temperatures. The resulting granulates are then sorted, screened, and cleaned before packaging.

Devulcanisation, on the other hand, breaks down the cross-linking bonds of natural rubber, a process that can be achieved through thermochemical, physical, or biological means. However, this method can lead to a degradation of rubber properties.

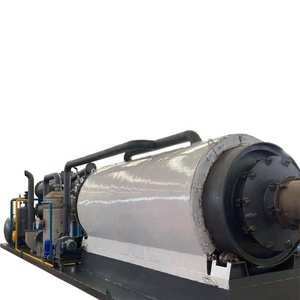

Another innovative approach is pyrolysis, a thermochemical process that heats shredded tires in an oxygen-free environment, breaking down the vulcanised molecules into smaller compounds. This process yields valuable outputs such as Carbon Black, gas, oil, and other chemicals, with the potential for high material recovery rates.

These technologies are part of a broader effort to promote sustainable development within the tyre recycling industry, aligning with the EU’s waste management regulations and the tire industry’s 7Rs hierarchy, which emphasizes reduction, reuse, recycling, redesign, renewal, repair, and recovery.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4