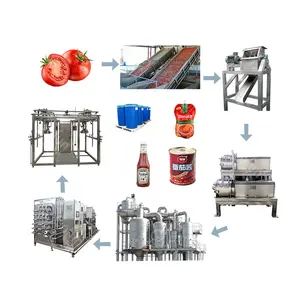

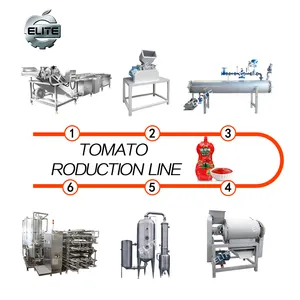

Introduction to Tomato Paste Processing Plants

Tomato paste processing plants are comprehensive industrial setups designed to convert raw tomatoes into a variety of processed tomato products. These facilities are equipped with advanced machinery to handle large-scale production, ensuring a steady supply of tomato-based ingredients for various culinary applications.

Types and Applications

The versatility of tomato processing equipment allows for the production of not just paste but also ketchup, purees, and other tomato condiments. These plants cater to a broad spectrum of applications, from food service providers to retail product manufacturers, offering an array of processed tomato forms to meet diverse market demands.

Features and Operation

A tomato paste maker is typically characterized by its robust construction, often utilizing stainless steel for durability. The operation of these plants is predominantly automated, with manual controls available for precision adjustments. This balance of automation and manual intervention ensures both efficiency and adaptability in production.

Materials and Advantages

Constructed from enduring materials, a tomato sauce making machine is designed for longevity. The incorporation of energy-saving features contributes to a more sustainable production process. Additionally, the machinery's quiet operation and anti-corrosive bearings are indicative of the thoughtful engineering that goes into these plants.

Capacity and Customization

With capacities ranging from 20 to 1,500 tons per day, a tomato processing line can be tailored to suit the scale of any business operation. The option for customization allows buyers to specify their requirements, ensuring that the plant aligns perfectly with their production goals and space constraints.

Additional Functionalities

Beyond paste and sauce creation, some tomato processing machines come with additional functionalities, such as vegetable washing, crushing, and even packaging capabilities. This multi-functionality not only streamlines the production process but also enhances the overall value of the plant.

In conclusion, a tomato paste processing plant represents a significant investment for businesses looking to scale up their tomato product offerings. The machinery's robust design, coupled with its versatile applications and customizable features, make it a crucial component in the food processing industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4