Introduction to Textile Spinning Machines

Textile spinning machines are integral components in the fabric production industry, transforming raw fibers into yarns that are subsequently woven or knitted into fabrics. These machines have evolved significantly, incorporating advanced technology to enhance efficiency and productivity in yarn manufacturing.

Types and Applications

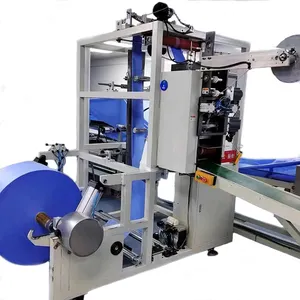

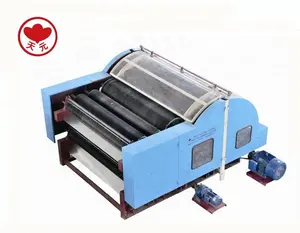

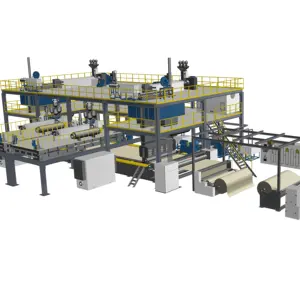

Spinning machines come in various types, each suited to specific fiber types and end-use applications. From the robust ring spinning machines to the efficient rotor spinning machines, the choice of equipment impacts the texture and quality of the yarn produced. These machines serve a critical role in producing a wide range of yarns used in everything from clothing to industrial textiles.

Operational Features and Efficiency

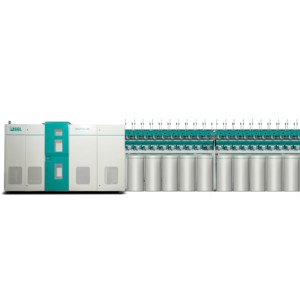

Modern textile spinning machines are designed with adjustable settings to ensure consistent productivity. They often feature high-speed production modes, which are crucial for meeting the demands of fast-paced textile markets. The emphasis on operational efficiency is matched by a commitment to safety and ease of use, with many models boasting automated production lines that require minimal monitoring.

Materials and Maintenance

The construction of spinning machinery involves durable materials that withstand the rigors of continuous operation. The ease of maintenance and the availability of replaceable mechanical parts contribute to the longevity of these machines, ensuring they remain a staple in factories for years. This durability is a key factor in maintaining a steady production flow and minimizing potential downtimes.

Advantages of Modern Spinning Technology

The advanced technology employed in contemporary spinning equipment provides numerous advantages. These include lower operational costs due to reduced maintenance needs and energy-efficient designs that cater to sustainable manufacturing practices. Additionally, the compact packaging of these machines safeguards them during transit, ensuring they arrive at production facilities in optimal condition.

Selecting the Right Spinning Machine

When sourcing a textile spinning machine on Alibaba.com, it is important to consider the specific needs of your production line. Factors such as energy requirements, available factory space, and maintenance costs should influence the selection process. Prospective buyers are encouraged to review the diverse technologies available to identify the machine that best aligns with their production goals and sustainability standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4