Understanding Steel Rolling Mills

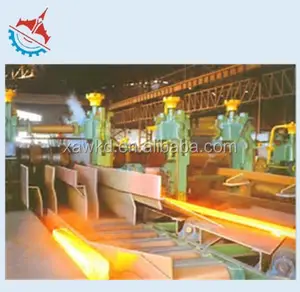

Steel rolling mills are integral components in the world of metalworking, serving a pivotal role in the transformation of metal into various forms and shapes. These mills are designed to process a wide range of metals, with steel being the primary material, through the application of heat and pressure. The process involves passing metal stock through one or more pairs of rolls to reduce thickness, create uniformity, and impart desired mechanical properties.

Types and Applications

The versatility of steel rolling mills is evident in the variety of types available, each suited to specific tasks. From hot rolling mills that are ideal for shaping steel in its pliable, heated state to cold rolling mills used for precision and surface finish enhancement, the selection caters to diverse industrial needs. These mills are commonly employed in the construction of infrastructure, manufacturing of automotive components, and production of household appliances, to name a few applications.

Features and Materials

A steel rolling mill is characterized by its robust construction and the use of durable materials capable of withstanding the rigors of metal processing. Components are typically crafted from hardened steel or other alloys that offer resistance to wear and deformation. The design of a mill also includes features that promote efficiency, such as automated control systems and cooling mechanisms to maintain optimal operating temperatures.

Advantages of Steel Rolling

The adoption of a steel rolling mill in metalworking brings forth several advantages. It enhances productivity through high-speed production and ensures uniform thickness across rolled products. The process also contributes to the improved strength and grain structure of the steel, making it suitable for a wide range of high-stress applications. Furthermore, the ability to customize the rolling process allows for the creation of steel with specific characteristics, tailored to industry requirements.

Selection Considerations

When selecting a steel rolling mill, factors such as capacity, rolling speed, and the type of steel to be processed are crucial. Mills are available in different sizes, from compact units suitable for small-scale operations to large-scale industrial machines. The choice of a mill should align with the intended application and production volume, ensuring that the equipment can meet the demands of the operation.

Complementary Equipment

In addition to the primary rolling equipment, complementary machinery such as crushing tools and stamp mills can be integrated into the workflow for pre- and post-rolling processes. These machines assist in preparing raw materials and refining the final product, contributing to the overall efficiency and quality of the metalworking operation.

Incorporating a steel rolling mill into your metalworking process can significantly enhance production capabilities. While Alibaba.com serves as a marketplace to connect you with suppliers, it is essential to conduct thorough research and engage with experienced manufacturers to find the equipment that best suits your operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4