Introduction to Steel Rolling Mill Plants

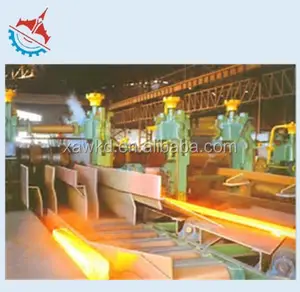

Steel rolling mill plants are integral components of the metalworking industry, facilitating the production of steel in various forms and sizes. These plants encompass a range of machinery and tools designed to process steel by deforming it between rolls to produce the desired shape. The versatility of steel rolling plants allows for the production of everything from thin sheets to heavy plates, catering to diverse industrial needs.

Types and Applications

The variety of rolling mills within a steel rolling mill plant includes the hot strip mill, cold rolling mill in steel plant, and sections dedicated to finishing processes. Each type serves a specific purpose; for instance, a hot strip mill in steel plant is typically used for initial rolling of steel slabs, while cold rolling mills fine-tune the thickness and surface. Applications range from construction materials to automotive components, underscoring the plants' extensive utility.

Features and Materials

A steel rolling mill plant is characterized by its robust construction and the use of durable materials capable of withstanding the high-stress environment of metal deformation. Components such as the roughing mill in steel plant or the heavy plate mill are engineered for longevity and performance, ensuring consistent output over time.

Advantages of Modern Rolling Mills

Modern advancements have led to the development of sophisticated mills like the danieli hot rolling mill and the nucor plate mill, which offer enhanced efficiency and precision. The integration of automation and control systems in these plants not only improves production rates but also contributes to the reduction of steel rolling mill plant cost, making the investment more viable for producers.

Choosing the Right Steel Rolling Mill Plant

Selecting the appropriate rolling mill is crucial for operational success. Factors such as production capacity, the specific type of steel products required (e.g., wire rod mill tata steel or jsw plate mill), and the projected tmt rolling mill project cost should guide the decision-making process. While Alibaba.com does not endorse any particular brand, the platform offers a comprehensive listing of suppliers to meet diverse needs.

Conclusion

In conclusion, steel rolling mill plants are essential for the production of steel products. With a range of types and applications, these plants are designed to meet the needs of the steel industry. By choosing the right plant and understanding the associated costs, such as the cost of rolling mill plant, businesses can effectively meet their production goals. Alibaba.com serves as a marketplace to connect buyers with a plethora of suppliers offering various rolling mill solutions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4