Spray Foam Insulation Machine is equipment for foaming polyurethane insulation material. It can spray polyurethane foam onto the exterior walls, roofs and floors of buildings to provide thermal insulation.

Common professional spray foam equipment

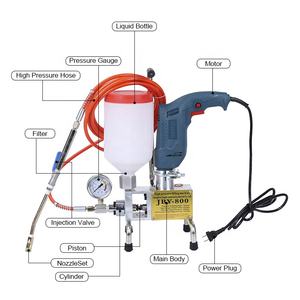

An industrial spray foam machine is a large, professional spray foam equipment mainly used for thermal insulation spraying in the industrial field. This type of spray foam equipment is characterized by high efficiency, large capacity and continuous production. A portable spray foam machine for sale is a lightweight and flexible spraying equipment suitable for on-site construction, maintenance and other occasions. This spraying equipment can be easily carried and moved, suitable for different working environments and needs.

A commercial foam insulation machine is a kind of spraying equipment suitable for commercial fields, mainly used for building thermal insulation waterproof and moisture-proof construction. This spraying equipment is characterized by high efficiency, environmental protection and safety, which can meet the requirements of the commercial field for aesthetics and practicality.

How can to improve the thermal insulation effect of a spray foam insulation machine?

1. Optimize foam formulation: It can be developed and optimized for different use environments and needs to improve its heat preservation and insulation performance. For example, by adding special flame retardant and foaming agent, we can prepare foam material with good flame retardant properties, high foaming multiplication and excellent heat preservation and insulation effect. 2. Increase the thickness of foam: Increasing the thickness of foam can improve the heat preservation and insulation effect. By spraying thick layers of foam, the internal and external temperature conduction can be reduced, and the indoor temperature can be kept stable. At the same time, the thick layer of foam can also improve the strength and durability of the foam itself.

3. Improve the uniformity of spraying: The uniformity of spraying greatly influences the thermal insulation effect. If the spraying is uniform, the thickness and density of the foam will be smooth, resulting in better thermal insulation. Therefore, when using professional spray foam insulation equipment, attention should be paid to ensuring spraying foam. 4. Reduce the air layer: Air is a good heat insulator, so care should be taken to reduce the air layer when using a spray insulation machine. The air layer can be reduced by using adhesive or sealant on the surface of the building, etc. so that the foam can be closely combined with the building.

5. Improvement of construction quality: The quality of construction greatly influences the effect of thermal insulation. When using a spray foam insulation machine, attention should be paid to improving the construction quality to ensure that the flatness and thickness of the foam meet the requirements. At the same time, after the construction is completed, the foam should be cared for and maintained to prevent it from being damaged or contaminated.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4