Introduction to Spin Coating Machines

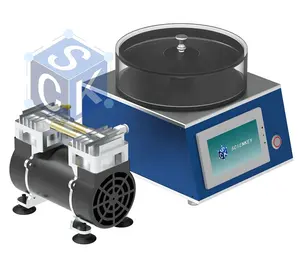

Spin coating machines are essential tools in the field of material science and production, designed for depositing uniform thin films onto flat substrates. Typically used in the microelectronics industry, these machines apply centrifugal force to spread a solution across a substrate, creating a thin, even coating.

Types and Applications

There are various types of spin coaters catering to different industrial needs. From simple manual systems to advanced programmable models, spin coaters are utilized in creating films for semiconductor devices, compact discs, and flat panel displays. Their applications extend to laboratories for research and development, particularly in the creation of thin-film solar cells, and in the field of nanotechnology.

Technical Features

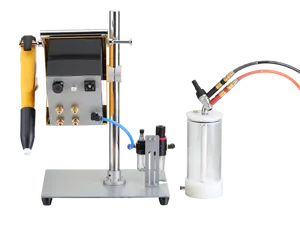

A spin coating machine typically comprises a spin chuck to hold the substrate, a motor to rotate the chuck, and a system to dispense the coating material. Advanced models may include features such as digital control panels, programmable spin cycles, and vacuum chucks to securely hold substrates of various sizes.

Material Compatibility and Advantages

Spin coaters are compatible with a range of materials including polymers, oxides, and photoresists. The advantage of using a spin coating apparatus lies in its ability to produce extremely uniform layers, crucial for high-precision manufacturing. Additionally, the process is relatively quick and can be easily integrated into various production lines.

Choosing the Right Spin Coater

Selecting the appropriate spin coating equipment depends on several factors such as the required film thickness, the viscosity of the coating material, and the size of the substrate. Buyers should consider the machine's adjustability, speed range, and substrate compatibility to ensure it meets their specific application requirements.

Maintenance and Sustainability

Maintaining a spin coating system involves regular cleaning and calibration to ensure consistent performance. Sustainability is another aspect, as these machines contribute to material conservation by minimizing waste during the coating process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4