Introduction to Spin Cast Machines

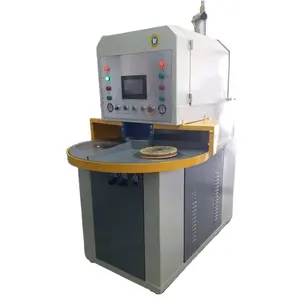

Spin cast machines, a pivotal category in the metalworking industry, serve a specialized role in shaping molten metal into predefined forms. These machines utilize a die to cast materials into intricate shapes, a process central to numerous manufacturing sectors. The versatility of spin cast mold technology enables its application across various metals, enhancing its utility in the production landscape.

Types and Applications

The spectrum of spin cast machines includes diverse types, such as centrifugal spin casting machines and lead spin cast machines. Each variant caters to specific metalworking tasks, from creating robust machine components to delicate jewelry pieces, highlighting the jewelry spin casting machines as a subset of this category. The adaptability of these machines allows for their use in automotive, aerospace, and artisanal crafts, demonstrating their expansive application range.

Features and Materials

A spin casting machine's efficacy is derived from its construction and the materials it handles. Machines designed for spin casting mold making are engineered to withstand the high temperatures and pressures involved in metal casting. The materials processed range from aluminum and zinc to pewter, with pewter spin casting machines being particularly sought after for their ability to handle lower melting point metals with precision.

Advantages of Spin Casting

The strategic advantage of employing a metal spin casting machine lies in its efficiency and precision. Spin casting equipment offers a reliable method for producing high volumes of components with consistent quality. The process is less labor-intensive compared to traditional casting methods, which translates into a more streamlined production cycle.

Choosing the Right Machine

Selecting the appropriate spin cast machine hinges on understanding the specific requirements of the task at hand. Factors such as size, power, and capacity are crucial when considering a diy spin casting machine or a more industrial model. For businesses looking to expand their capabilities, used spin casting machines provide a cost-effective alternative without compromising on functionality.

Conclusion

In conclusion, spin cast machines are integral to the metalworking industry, offering a range of solutions for various casting needs. With a comprehensive inventory available on Alibaba.com, businesses can find the right machinery to meet their production demands without the hassle of navigating through countless suppliers. It's essential to assess the specifications and features of each machine to ensure it aligns with your production goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4