Introduction to Sheet Metal Straighteners

Sheet metal straighteners are essential tools in the metalworking industry, designed to flatten and prepare metal sheets for further processing. These machines are pivotal in ensuring that the metal's surface is free from distortions and is uniformly flat, which is crucial for high-precision manufacturing tasks.

Types and Applications

There are various types of sheet metal straighteners tailored to different sizes and thicknesses of metal. Some are adept at handling large rolls of metal for heavy-duty operations, while others cater to smaller, more delicate materials. Their applications span across automotive, aerospace, and construction industries, where the integrity of metal shapes and surfaces is paramount.

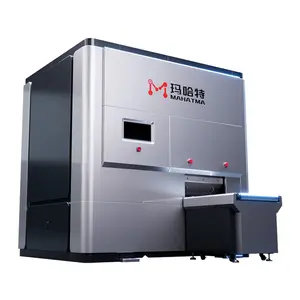

Features and Design

The design of a metal sheet straightening machine focuses on durability and efficiency. These machines typically feature a series of rollers that incrementally straighten the metal as it passes through. The robust construction of these machines ensures they can withstand the rigors of continuous operation without compromising performance.

Materials and Construction

Constructed from wear-resistant materials, metal straighteners are built to last. The choice of materials also influences the machine's ability to resist corrosion and maintain accuracy over years of service in varying industrial environments.

Advantages of Utilizing Sheet Metal Straighteners

Using a precision sheet metal straightener brings numerous advantages to manufacturing processes. It enhances the quality of the final product by ensuring metal sheets are free from warps and bends before cutting or shaping. This precision leads to a reduction in material waste and increases the efficiency of the manufacturing process.

Choosing the Right Machine

Selecting the appropriate sheet metal straightener is a critical decision for any manufacturing operation. Factors to consider include the material type, size capacity, and the specific requirements of the manufacturing process. While Alibaba.com does not manufacture these machines, the platform offers a diverse array of options from various vendors, enabling buyers to compare and find the machine that fits their operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4