Understanding Roll Mill Stands

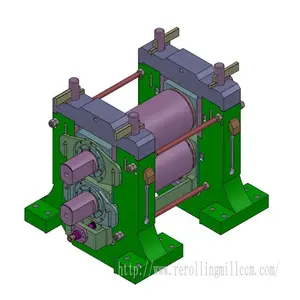

A roll mill stand is a fundamental component in the metalworking field, specifically in rolling mills. It serves as the backbone for the rolling process, where metal stock passes through one or more pairs of rolls to reduce thickness, create uniformity, and/or impart a desired mechanical property. The versatility of roll mill stands allows them to be a part of various setups, catering to different rolling processes such as hot rolling and cold rolling.

Types and Configurations

There are several types of roll mill stands, each designed to fulfill distinct rolling requirements. The two-high stand, the three-high stand, the four-high stand, and the cluster stand are common configurations, each offering various advantages for specific rolling operations. The selection of a roll mill stand type is crucial and is typically based on the balance between desired material properties and production efficiency.

Applications Across Industries

The application of roll mill stands spans across various industries, from manufacturing plants to construction and agricultural sectors. They play a pivotal role in shaping and forming metal products such as sheets, bars, and rods, which are integral to countless industrial applications. Their importance is particularly pronounced in sectors where precise metalworking is essential.

Features and Materials

A roll mill stand is characterized by its robust construction and design to withstand the high stresses involved in rolling processes. The materials used for these stands are typically high-strength steel or cast iron, chosen for their durability and ability to resist wear and deformation. Additionally, modern stands may incorporate advanced features like hydraulic roll gap control and quick roll changing systems to enhance productivity and accuracy.

Advantages of Modern Roll Mill Stands

Modern roll mill stands are engineered to provide superior performance and efficiency. They are designed for ease of maintenance and operation, with features that reduce downtime and increase throughput. The precision with which these stands operate allows for better control over the final product's dimensions and surface finish, which is critical in producing high-quality metal products.

Choosing the Right Roll Mill Stand

Selecting the appropriate roll mill stand involves considering the specific requirements of the rolling process, including the type of material to be rolled, the desired thickness reduction, and the production volume. It is essential to assess the compatibility of the stand with existing rolling mill machinery and to ensure that it can be integrated seamlessly into the production line.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4