Introduction to Primer Machines

Primer machines are essential tools in the woodworking and carpentry industries, serving as the foundation for efficient and precise preparation of materials. These machines are designed to prime surfaces, ensuring they are ready for subsequent processes such as painting or varnishing. The importance of a reliable primer machine in professional woodworking cannot be overstated, as it directly impacts the quality and durability of the finished product.

Types of Primer Machines

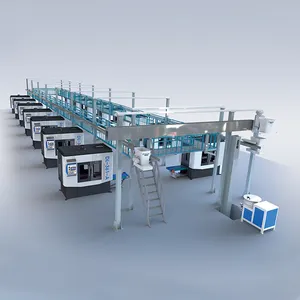

The variety of primer machines available caters to different needs and scales of operation. From benchtop models suitable for smaller workshops to industrial-grade machines for high-volume production, the selection is tailored to fit diverse requirements. Each type of primer machine offers unique features, whether it's precision in application, speed of operation, or the ability to handle various material sizes and shapes.

Applications and Features

Primer machines are not limited to a single application. They are versatile and can be used across various woodworking tasks, including but not limited to, door and window frames, cabinetry, and furniture making. Key features to consider when selecting a primer machine include adjustable settings for different material types, ease of operation, and consistent performance. These features ensure that the machine can adapt to the specific needs of each project, providing a uniform coat and optimal surface preparation.

Materials and Advantages

Constructed from durable materials, primer machines are built to withstand the demands of continuous operation. The use of high-grade components ensures longevity and reduces the need for frequent maintenance. The advantages of incorporating a primer machine into your woodworking process include increased efficiency, improved finish quality, and the ability to handle a high volume of work with consistent results.

Choosing the Right Primer Machine

Selecting the right primer machine requires careful consideration of your specific production needs. Factors such as the size of the items to be primed, the volume of work, and the type of materials used are crucial in making an informed decision. It is important to compare the different machine specifications and features to find the one that aligns with your operational requirements.

Enhancing Your Woodworking Operations

Incorporating a primer machine into your woodworking operations can significantly enhance efficiency and product quality. With a focus on precision and adaptability, these machines are an investment in your business's productivity. By choosing the appropriate machine, you can ensure a smooth and effective priming process, laying the groundwork for excellent finishing work.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4