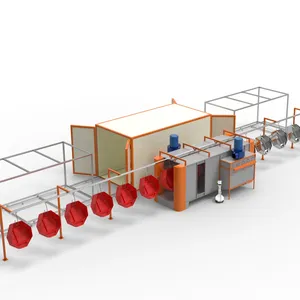

A powder coating machine is a crucial tool in the industrial sector. It functions to apply a coating of powder to a surface, typically a metal, through the use of an electrostatic or compressed air method. This process offers an extremely durable finish that is resistant to chipping, scratching, fading, and wearing. Powder coating machines are extensively used in numerous industries, including automotive, aerospace, home appliances, and construction.

Types of powder coating machines

There are multiple types of powder coating machines available in the market, each with unique characteristics and applications. One of the commonly used types is the electrostatic powder coating machine. This type of machine uses an electrostatic charge to apply the powder to the metal surface. The charged powder particles adhere to the metal surface until they are heat-cured into a smooth coating. Another type of powder coating machine is the small powder coating machine. Despite its compact size, this machine is highly efficient and is ideal for small-scale operations or businesses with limited space. Its small size does not compromise its performance or the quality of the finish it produces. In addition to these, there is also the portable powder coating machine. As the name suggests, this machine is designed for mobility and ease of use. It is a convenient option for on-site applications, making it popular among contractors and mobile businesses.

Features of a powder coating machine

The features of a powder coating machine and oven vary depending on the model and type. However, there are certain key features that are common to many machines. One of the fundamental features is the ability to apply a uniform layer of powder. This ensures a smooth and even finish, which is essential for the durability and aesthetic appeal of the coated product. Another important feature is the machine's efficiency. An efficient powder coating machine should be able to coat a large surface area quickly without compromising the quality of the finish. This is particularly critical in high-volume production settings where speed and efficiency are paramount. Safety features are also a crucial aspect of a powder coating machine. The machine should be designed and built to meet the safety standards and regulations of the industry. This includes features such as protective casings, emergency stop buttons, and safety interlocks.

Materials used in a powder coating machine

A powder coating machine is generally constructed from high-grade materials to ensure its durability and longevity. The main body of the machine is typically made from steel or other robust metals to withstand the rigors of the industrial environment. The internal components, such as the powder hopper and the powder pump, are often made from materials like stainless steel or aluminum, which are known for their corrosion resistance. The material of the coating powder is also a significant factor. It is typically a mixture of finely ground particles of resin and pigment, along with other additives that enhance its performance. The powder can be either thermosetting or thermoplastic, depending on the application.

In conclusion, a powder coating machine is a versatile and efficient tool that offers numerous benefits. By understanding its types, features, and materials, one can make an informed decision when purchasing or using such a machine.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4