What is Plastic Sheet Cutter Machine

Plastic sheet cutter machines are vital tools in various industries that deal with plastic materials. These machines serve the purpose of cutting plastic sheets into specific dimensions and shapes, catering to the needs of manufacturers, retailers, and businesses that require precise and efficient cutting of plastic materials for their products and operations. The utility of a plastic sheet cutter machine is not limited to just cutting; some models may also incorporate features like scoring, punching, and milling to further shape or alter the plastic material to fit different manufacturing requirements.

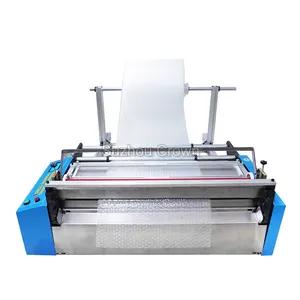

The working principle of plastic sheet cutter machines typically involves feeding a plastic sheet through a series of blades or rollers that make the necessary cuts. These machines can vary in their operation, with some using shear force to slice through materials while others may employ a scissor-like cutting action. The choice of cutting method often depends on the type of plastic being used, its thickness, and the required finish.

These machines are designed with precision and accuracy in mind to ensure that the final cut is clean, smooth, and meets the required specifications. Various factors such as material composition, thickness, and cutting speed can influence the type of machine used and the way it operates. The use of plastic sheet cutter machines not only enhances the production process but also helps in maintaining consistent quality and meeting industry standards.

Types of Plastic Sheet Cutter Machine

The market offers a diverse array of plastic sheet cutter machines tailored to meet specific needs across various industries. Here are some common types:

-

Handheld Plastic Sheet Cutters: These are compact and portable, ideal for manual cutting of thin plastic sheets or for intricate designs that require precision. They are commonly used in signage shops or by hobbyists.

-

Automatic Plastic Sheet Cutters: Equipped with motors and often PLC controls, these machines can make quick work of cutting large volumes of sheets. They're typically found in manufacturing plants where high efficiency is crucial.

-

Hot Knife Plastic Sheet Cutters: With a heated blade that cuts through plastic using less force, these machines are suitable for materials that are difficult to cut with cold blades. They're used in various applications including foam cutting and packaging.

-

Hydraulic Plastic Sheet Cutters: These heavy-duty machines are used for thick sheets or in applications where larger force is required. Hydraulic systems can handle high-capacity cutting with ease.

-

Guillotine Shears: Employed for cutting both sheet and roll materials, guillotine shears use a straightforward lever design to achieve clean cuts. They are particularly useful for cutting thicker materials.

Each type has its own set of core components such as motors, blades, and control systems that dictate their functionality and best use cases.

How to choose Plastic Sheet Cutter Machine

When selecting a plastic sheet cutter machine for your business needs on Alibaba.com, consider the type of material you will be working with regularly. For instance, if you frequently cut high-density plastics like polycarbonate or acrylic, a machine with a laser source suitable for these materials would be ideal. On the other hand, if you primarily deal with low-density plastics such as polyethylene or polypropylene, you might opt for a rotary cutter due to its efficiency in handling such materials.

Also, factor in the volume of work and the desired end-product specifications. Machines vary in their capacity to handle sheets of different sizes and thicknesses. Consider whether you need a fully automatic machine for high-volume production or a more affordable semi-automatic machine that offers greater flexibility in terms of material loading and unloading.

Finally, assess after-sales support options such as online support or video technical support which can be crucial for resolving any operational issues you may encounter after making a purchase.

About Plastic Sheet Cutter Machine on Alibaba.com

For businesses seeking reliable plastic sheet cutting solutions, Alibaba.com stands out as a premier global marketplace connecting buyers with a vast network of suppliers. It offers an extensive selection of plastic sheet cutter machines that cater to various industrial needs—from retail shops requiring precise packaging to manufacturers needing specialized components for product assembly.

Alibaba.com simplifies the sourcing process by providing detailed product descriptions and supplier transparency, ensuring businesses can make informed decisions tailored to their specific requirements. With features such as Trade Assurance, buyers have added peace of mind knowing their transactions are secure until delivery is completed.

Moreover, Alibaba.com's platform accommodates businesses across more than 190 countries by featuring suppliers who offer a wide range of plastic sheet cutter machines suitable for various applications. Whether your business operates within advertising, construction, or manufacturing, Alibaba.com provides access to cutting-edge equipment that meets quality standards while emphasizing efficiency and productivity.

Common FAQs for Plastic Sheet Cutter Machine

What is a plastic sheet cutter machine used for in industrial settings?

Plastic sheet cutter machines are used to precisely cut plastic sheets into different shapes and sizes, typically used in industries such as advertising, packaging, aerospace, automotive, and manufacturing for various parts and products.

Can plastic sheet cutter machines handle different types of plastics?

Plastic sheet cutter machines are designed to handle a variety of plastic materials including acrylic, ABS, PP, PE, PVC, and sheets with different surface finishes or textures.

Are there plastic sheet cutter machines suitable for small-scale businesses or hobbyists?

Yes, there are plastic sheet cutter machines designed for small-scale businesses and hobbyists. Handheld or desktop models are available that are suitable for limited production runs or personal use.

What should I consider when choosing a plastic sheet cutter machine for my business?

When choosing a plastic sheet cutter machine, consider the types of plastic materials you will be working with, the thickness and size of the sheets, the machine's cutting capacity and precision, ease of use, safety features, and whether it offers after-sales support.

How do I ensure the plastic sheet cutter machine meets safety standards?

Ensure that the plastic sheet cutter machine you select complies with industry safety standards by checking for certifications or product specifications that indicate safety features such as emergency stop buttons and protective guards.

What is the core material in a CNC plastic sheet cutter machine?

The core material in a CNC plastic sheet cutter machine is critical as it provides stability for the cutting tool and workpiece during the cutting process, ensuring precision and consistency in the operation.

Can I use a plastic sheet cutter machine for materials other than plastic?

While plastic sheet cutter machines are primarily designed for plastic materials, some models may have the capability to cut other materials like thin metals or foams. It is important to review the specifications of each machine to determine its material compatibility.

How often does a plastic sheet cutter machine need maintenance?

Maintenance frequency will depend on the machine's usage intensity but generally involves regular checks for blade sharpness, lubrication for moving parts, and ensuring that the safety features are functioning correctly.

What is the expected lifespan of a plastic sheet cutter machine?

The lifespan of a plastic sheet cutter machine varies depending on its build quality, usage frequency, and maintenance practices. With proper care, some machines can last several years before requiring replacement parts or servicing.

Are there different types of blades for plastic sheet cutter machines?

Yes, there are various blade types available for plastic sheet cutter machines including straight blades, rotary cutters, and dual blades. The choice of blade will depend on the material being cut and the desired finish quality.

Can I get a customized plastic sheet cutter machine based on specific business needs?

While customization options may vary by supplier, many manufacturers offer some level of personalization for plastic sheet cutter machines based on specific business requirements such as blade specifications or machine dimensions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4