What is Plastic Recycling System

Plastic recycling systems are sophisticated machinery designed to reclaim and process various types of plastic waste, turning them into reusable pellets, flakes, or granules. These systems are an essential component of the circular economy, providing a sustainable solution for managing plastic waste and minimizing its environmental impact. They cater to a wide range of users, from small businesses to large industries, that are committed to reducing their plastic footprint and contributing to a more resource-efficient future.

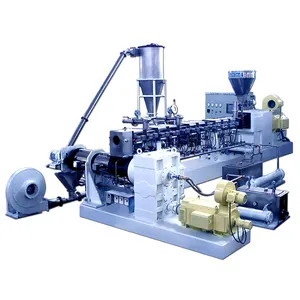

The operation of a plastic recycling system involves several stages, starting with the collection of plastic waste. This collected material then undergoes a series of processes such as sorting, shredding, washing, and melting to remove contaminants and break it down into a form that can be easily processed into new plastic products. Advanced systems may include additional steps like pelletizing, extrusion, and compounding to produce high-quality recycled plastic materials that can be used in the manufacturing of new plastic items.

Plastic recycling systems are built on principles that promote efficiency, safety, and environmental responsibility. They are often equipped with features like automatic operation, which can significantly reduce labor costs and improve productivity. Furthermore, these systems play a crucial role in waste management by ensuring that plastic waste is collected efficiently and processed correctly, thereby preventing its accumulation in landfills and oceans.

Types of Plastic Recycling System

The market offers a variety of plastic recycling systems tailored to meet different needs and applications. Each type supports the recycling of specific types of plastic or is best suited for particular industrial processes:

-

Local Service Location Recycling System: These systems are designed for communities or businesses that wish to recycle on a larger scale. They often include heavy-duty machinery for sorting and processing plastic waste and can be tailored for specific material streams.

-

Industrial Plant Recycling System: Aimed at manufacturing plants, this type of system manages the recycling of plastic materials generated from industrial processes. It may involve complex sorting mechanisms or specialized equipment for handling large volumes of plastic.

-

Portable Plastic Recycling System: For events, catering services, or businesses that generate small amounts of plastic waste, portable systems offer flexibility and convenience. They can be easily transported between locations and used to encourage recycling efforts on a temporary basis.

-

Plastic Packaging Recycling System: This kind of system is focused on recovering and processing plastic packaging such as bottles and jars. It plays a critical role in the circular economy by keeping plastic packaging out of landfills and encouraging its reuse.

Each system has its own set of core components like motors, gearboxes, or pumps, which are selected based on their compatibility with various recycling processes and material types. The dewatering machine, floating washing tank, and hot air dryer are common equipment used in these systems to clean and prepare plastic materials for resale.

How to choose Plastic Recycling System

Selecting the appropriate plastic recycling system requires careful consideration of several factors to ensure that it meets your business needs effectively. Here's what businesses should consider:

-

Material Type: The type of plastic you intend to recycle will significantly influence your choice. For instance, if your business specializes in PET bottle recycling, then a system designed specifically for this material would be necessary.

-

Capacity: The volume of material you plan to process is another critical factor. Systems vary widely in terms of their capacity ranging from small-scale to large-scale operations. Choosing one that aligns with your production output will optimize efficiency.

-

End Product Quality: The quality of the end product will be a key consideration. If you're aiming for high-grade materials suitable for direct consumer use, then investing in systems that produce clean and sorted plastics will be crucial.

-

Space Availability: The physical space you have available will also dictate the size and type of system you can implement. Compact systems that fit within a smaller footprint may be more suitable for cramped facilities.

-

Regulatory Compliance: Ensure that the system you choose meets all relevant environmental regulations and codes pertaining to waste management within your region.

Taking these considerations into account will help you make an informed decision when integrating a plastic recycling system into your business operations.

About Plastic Recycling System on Alibaba.com

Alibaba.com stands out as a premier online marketplace where businesses around the globe can discover a comprehensive selection of Plastic Recycling Systems tailored to their specific needs. The platform's extensive network of suppliers ensures that whether you're in manufacturing plants, construction companies, or food shops, you'll find a system that meets your industry's standards for sustainability and efficiency.

With its user-friendly interface available in multiple languages and advanced mobile features, Alibaba.com makes it simple for buyers to connect with suppliers and negotiate deals from any corner of the world. The platform's commitment to facilitating trade is evident through services like Trade Assurance which safeguards payments until delivery is confirmed, instilling confidence in each transaction.

Moreover, Alibaba.com's vast array of options allows businesses to source systems that cater to their unique requirements—be it high productivity for large-scale operations or specialized equipment for handling certain types of plastics. This adaptability positions Alibaba.com as an invaluable resource for companies aiming to enhance their recycling capabilities and contribute to a more sustainable future.

Common FAQs for Plastic Recycling System

What is a plastic recycling system?

A plastic recycling system is a facility or process that converts plastic waste into reusable material. It typically involves collecting and sorting plastic waste, shredding it into flakes, and then melting it down to form new plastic products.

Can all types of plastics be recycled?

Not all plastics can be recycled. Plastics that are categorized as recyclable include PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and PE (Polyethylene). The recyclability of a plastic depends on its resin code, with 1 and 2 being the most commonly recycled types.

What are the main components of a plastic recycling system?

The main components of a plastic recycling system include a feeding system, a shredder or granulator for size reduction, a washing system for cleaning the plastics, an extruder to melt and reform the plastics into pellets or flakes, and a dryer for removing moisture.

How does a single-screw extruder differ from a co-rotating conical twin-screw extruder?

A single-screw extruder uses a single rotating screw to feed the material and melt it, while a co-rotating twin-screw extruder has two rotating screws that move in the same direction, causing the material to heat up and become homogenous.

What is the advantage of a hot air dryer in a plastic recycling system?

A hot air dryer can be used to dry shredded plastic into a material with specific properties, which is beneficial for subsequent processing stages in a recycling system. It is also effective in reducing the moisture content of the recycled material.

How do I determine the right size of plastic recycling system for my business?

Consider the volume of plastic waste your business generates, the types of materials you need to process, available space, and desired end-products. Assessing these factors will help you choose a system that meets your production requirements.

Are there any environmental benefits to using a plastic recycling system?

Yes, using a plastic recycling system helps reduce the environmental impact by diverting plastic waste from landfills. It also contributes to the circular economy by extending the life of plastic products through recycling.

What should I consider regarding the quality of the end-product from a plastic recycling system?

The quality of the end-product is influenced by the system's ability to generate uniform, high-quality granules or flakes that are free from contaminants. Quality is crucial when producing products that demand consistent material properties.

Can a plastic recycling system handle different types of waste?

Most plastic recycling systems are designed to handle various types of waste within their processing capabilities. However, it's important to check the specifications of each system to ensure it meets your specific needs.

How does a dewatering machine function in a plastic recycling system?

A dewatering machine usually consists of a filter screen or perforated plate that allows liquids to drain from the processed material. This is an essential step in recycling to prevent contamination of downstream equipment.

What types of support are available for maintenance and repair of a plastic recycling system?

Support services such as video technical support, online support, field maintenance and repair service, and engineers available for service machinery overseas are commonly provided by manufacturers to ensure proper operation of the equipment.

Is it possible to integrate a plastic recycling system with other machinery in my facility?

Yes, many plastic recycling systems can be integrated with other machinery to optimize material handling and processing efficiency. It's important to consult with the supplier about compatibility options.

How does the core screw design affect the performance of a plastic recycling system?

The core screw design of a system influences its performance by affecting the size reduction of the shredded material and the quality of the end-product. Different core screw designs are suited to handling various types of plastic waste.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4