What is Precision Pcb Milling Machine

Precision PCB milling machines are advanced devices that serve as the backbone for the manufacturing of precision printed circuit boards (PCBs). These machines are engineered to carve out intricate patterns on a laminated board, which is often coated with copper, to create a functioning PCB. They are essential tools for various industries, including electronics manufacturing, research and development labs, and educational institutions where precise and intricate PCB fabrication is a necessity.

The principle behind a precision PCB milling machine is its ability to control the milling process with high accuracy. This is achieved through a combination of mechanical systems and software that work in tandem. The machine's motorized spindle holds a cutting tool, such as an end mill or a drill bit, which removes material from the surface of the board according to the specifications of the design. The machine's control software allows operators to program the exact paths and depths of cut for each board, ensuring precise and consistent milling for large-scale production runs.

Users of precision PCB milling machines range from small businesses that require custom circuitry for their products to large corporations that produce sophisticated electronic devices. These machines are also instrumental in the research and development of new electronic components and technologies due to their ability to produce precise and repeatable results. As technology advances, these machines become more sophisticated and capable of milling boards with multiple layers and complex geometries.

Types of Precision PCB Milling Machine

The market offers several types of precision PCB milling machines, each tailored to specific application needs:

-

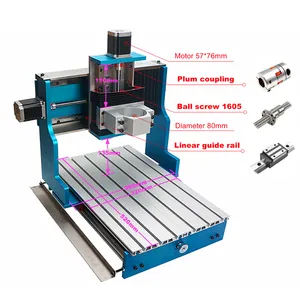

CNC Router: This type is characterized by its versatility in handling various materials. CNC routers are used not only for PCB milling but also for woodworking, sign making, and other tasks that involve precision cutting.

-

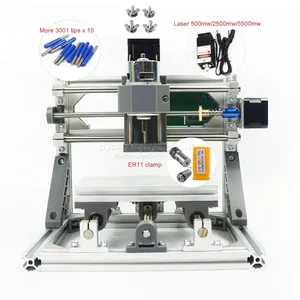

Desktop PCB Prototyping Machine: Compact and user-friendly, desktop machines are suited for small-scale production runs and rapid prototyping. They often feature interchangeable heads for milling, drilling, and engraving tasks.

-

Professional PCB Milling Machine: These machines are designed for larger production runs and include features such as automatic tool changers and conveyor systems. They are ideal for electronics manufacturers and large-scale prototyping efforts.

-

Specialized PCB Milling Machine: Some machines come with specific capabilities like handling rigid-flex PCBs or working with advanced materials like ceramics. These are used in specialized industries with unique requirements.

How to choose Precision Pcb Milling Machine

Choosing the right Precision PCB Milling Machine involves several considerations that reflect the nature of your business needs. Here's what you should keep in mind:

-

Machine Specifications: Evaluate the technical specifications such as spindle speed, resolution, and maximum board size to ensure they meet your requirements for precision milling.

-

Material Compatibility: Consider the type of materials you will be working with (like various grades of FR4) since different materials may require specific milling machine capabilities.

-

Software Compatibility: The software that comes with the machine should be user-friendly and compatible with the design software you will be using to create your PCB layouts.

-

Support and Maintenance: Check what kind of after-sales support is available such as online assistance or video technical support to ensure your operations run smoothly.

-

Customization: Some businesses may require customized features like an ATC (Automatic Tool Changer) or different coating options for end mills based on their specific manufacturing needs.

By carefully considering these factors in relation to your business operations, you can select a Precision PCB Milling Machine that offers a balance between performance, reliability, and cost-effectiveness.

About Precision Pcb Milling Machine on Alibaba.com

Alibaba.com stands as a global marketplace connecting buyers with suppliers offering a vast selection of precision PCB milling machines tailored to various industrial needs. With an emphasis on versatility and quality assurance, Alibaba.com hosts an extensive collection suitable for businesses ranging from small startups to large manufacturing plants. The platform's commitment to facilitating trade across borders ensures that businesses can find precisely what they need regardless of their geographic location.

Buyers looking for precision PCB milling machines will appreciate Alibaba.com's user-friendly interface which simplifies the search process through filters such as local service location, core components, machinery test reports, key selling points, and even control system brands. This feature-rich platform not only enhances buying convenience but also allows businesses to make informed decisions based on detailed product information.

Moreover, Alibaba.com's Trade Assurance service provides an additional layer of security by safeguarding payments until buyers confirm satisfactory delivery of their goods. This exemplifies Alibaba.com's dedication to not just providing a wide array of options but also ensuring a trustworthy trading experience. With its global reach and comprehensive support services, Alibaba.com empowers businesses to procure precision PCB milling machines that align with their operational requirements and budgetary considerations efficiently.

Common FAQs for Precision Pcb Milling Machine

What is the primary difference between a CNC mill and a manual milling machine?

A CNC (Computer Numerical Control) mill is a computer-controlled machine that automates the milling process, allowing for precise and efficient production of parts. A manual milling machine, on the other hand, requires more hands-on operation and is less automated.

How do I determine the right size CNC mill for my business needs?

Consider the scale of the parts you intend to produce. The size of the CNC milling machine should accommodate the largest piece you plan to work with. Additionally, factor in the complexity of the parts as well as the space available in your facility for the machine.

Can CNC mills be used for materials other than metal?

Yes, CNC mills can work with a variety of materials, including plastics, woods, and composites. The cutting tools and machine settings can be adjusted to suit the material being worked on.

What should I consider regarding the control system when purchasing a CNC mill?

Ensure that the control system is user-friendly for your operators and supports the file format used by your CAD software. Common control systems include Mach3, DSP, RichAuto, and Siemens among others.

Are there specific features to look for in a CNC mill for high-precision work?

Features such as high-accuracy, high-rigidity, and the ability to perform precision tasks like threading should be considered for applications that require high-precision results.

What after-sales services are important when purchasing a precision PCB milling machine?

Look for after-sales services like online support, video technical support, field maintenance and repair, and engineers available to service machinery overseas. These services can ensure ongoing support and maintenance for your CNC mill.

How do I ensure that the precision PCB milling machine I choose is durable?

Check the materials used in the construction of the machine and inquire about any additional coatings or treatments that may increase durability. Machinery test reports and supplier reputation can also be indicators of a machine's long-term performance.

Is it possible to customize a precision PCB milling machine for specific business needs?

Yes, many suppliers offer customized support such as OEM, ODM, or OBM services that allow businesses to tailor the machine to their specific requirements and use cases.

What kind of safety features should I look for in a precision PCB milling machine?

Safety features to consider include protective shields around the operating area, emergency stop buttons, and sometimes even automatic tool cooling systems that enhance safety during operation.

How does spindle speed affect the performance of a precision PCB milling machine?

Spindle speed determines the rate at which the milling tool removes material. Higher spindle speeds allow for faster cutting, while lower speeds may provide better surface finishes but are typically slower.

Can a precision PCB milling machine handle large-scale production?

Certain models of CNC milling machines are designed for high-volume production. It's important to review the machine's specifications to ensure it meets your production requirements.

Are there environmentally friendly options available among precision PCB milling machines?

While the focus is mainly on precision and performance, some machines may incorporate energy-saving features or be made from more sustainable materials. Look for suppliers who emphasize environmentally friendly practices.

What kind of maintenance is required for a precision PCB milling machine?

Regular maintenance includes cleaning, lubrication, and checking for wear on cutting tools. Depending on usage, you may also need to replace components or upgrade the software periodically.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4