Niehoff Wire Drawing Machine: An Overview

Wire drawing machines play a pivotal role in the transformation of wire, with the niehoff wire drawing machine standing out in the industry. These machines are engineered to modify the diameter of wires, tailoring them for a variety of industrial applications. From the production of high-tension springs to the intricacies of electronic repairs and the robustness of rebar production, the versatility of these machines is evident.

Types and Applications

The niehoff machine range includes several types, each designed to work with specific materials. For instance, the niehoff drawing machine tailored for steel is distinct from those meant for copper, gold, silver, or aluminum. This specialization ensures that each wire's material properties are maintained during the drawing process, resulting in a product that meets the precise needs of industries such as automotive, renewable energy, and electronics.

Features and Advantages

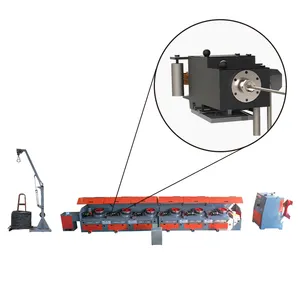

A niehoff multi wire drawing machine is designed for efficiency and versatility. Continuous wire drawing machines are optimized for high-volume production lines, while other models are more suitable for batch processing or individual tasks, ideal for smaller workshops. The integration of wire drawing and flattening capabilities in a single unit can be particularly beneficial for manufacturers of solar panels or automotive components, streamlining the production process.

Innovative Variants

In addition to standard models, innovative variants like the niehoff rbd machine (rod breakdown machine) and the niehoff bunching machine expand the capabilities of wire production. The former is known for its robust performance in creating finer wires, while the latter excels in the precise bunching of multiple wires, a critical step in the manufacturing of cables.

Enhanced Strength and Customization

For applications requiring enhanced wire strength, wet wire drawing machines are available, which use lubrication to reduce friction and heat, thereby preserving the wire's integrity. Meanwhile, wire pointing machines are instrumental in creating custom wire tips for specialized applications, demonstrating the adaptability of the niehoff drawing machine lineup to meet specific industrial requirements.

Conclusion

The niehoff wire drawing machine is a cornerstone in the realm of wire production, offering a range of solutions to meet diverse industrial needs. With a focus on innovation and precision, these machines are integral to the manufacturing processes of numerous sectors, ensuring that businesses have access to tailored wire products for their specific applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4