Metal Spinning Tools: An Overview

Metal spinning, also known as lathe spinning or metal turning, is a formative process that allows for the creation of axially symmetric parts by rotating a metal disc or tube at high speed and forming it to a mandrel. This technique is performed on a metal spinning lathe, which can range from simple manual equipment to highly sophisticated CNC spinning lathes. The process is versatile, capable of producing complex shapes in a single operation, which makes it a valuable method in various industrial applications.

Types of Metal Spinning Lathes

The spinning lathe machine is central to the metal spinning process. There are primarily two types: manual and automated. The manual spinning lathe is ideal for low-volume production and artisanal work, where the craftsman's skill is paramount. On the other hand, a CNC spinning lathe offers precision and repeatability for high-volume production. Advanced machines, like the Leifeld spinning machine, provide enhanced capabilities for intricate designs and are pivotal in industries requiring high precision, such as aerospace and automotive sectors.

Applications and Features of Metal Spinning

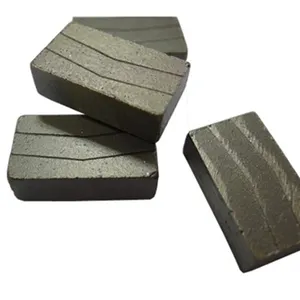

Metal spinning is employed in creating parts for numerous applications, from kitchen utensils to architectural components. The spinning machine for aluminium utensils is a common example of its application in the cookware industry. The process is also integral in producing musical instruments, lighting fixtures, and gas cylinders. Features of metal spinning tools include the spinning mandrel, which shapes the metal, and the metal spinning tool rest, which supports the tool during operation. These features contribute to the process's adaptability and efficiency.

Advantages of Metal Spinning

The advantages of using metal spinning tools are manifold. The process is economical for small to medium batch sizes and offers a quick turnaround. It also allows for considerable material savings, as the metal is deformed plastically, resulting in minimal waste. Furthermore, the ability to create complex shapes in a single operation reduces the need for multiple tools and processes, streamlining production and reducing labor costs.

Choosing the Right Metal Spinning Tools

Selecting the appropriate metal spinning tools is crucial for achieving desired outcomes. For hobbyists or those new to the craft, DIY metal spinning tools can be a starting point. Professionals might opt for specialized tools tailored to their specific needs, such as those used in a Pryibil spinning lathe for precision work. The choice of tools will significantly impact the efficiency and quality of the final product.

Conclusion

Metal spinning is a versatile and efficient process, integral to various industries. The choice of a metal spinning lathe, whether a manual or a Leifeld machine, should align with the intended application and production volume. With the right tools and equipment, metal spinning can produce high-quality components that meet the demands of any project.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4