A metal band saw is a power saw with a long, sharp blade that consists of a band of toothed metals that are continuous. These toothed metals on metal bandsaw blades are stretched between two or more wheels to cut materials. Here are two main types of metal band saws: horizontal band saws for metal and vertical metal cutting band saws. There are several metal band saws on Alibaba.com.

Uses of metal band saws

Metal band saws are used to cut metal bars and tubes that are used in construction, manufacturing, and fabrication. The materials can vary from steel to aluminum, brass, or any other type of alloy. The metal band saw ensures the cuts are straight and accurate. Therefore the band saw is good for cutting specific lengths of metal bars and tubes. Apart from cutting bars and tubes, metal cutting band saws are also used to cut metal plates and sheets. They feature adjustable tables that allow flexibility in cutting the different thicknesses of metal sheets. Metal band saws are ideal for such projects due to their accuracy and precision; they can create custom shapes or cut sheets into smaller and manageable pieces.

Metal band saws are also ideal for angle cutting in metals. They have miter gauges, which are used to make precise angled cuts. The miter gauges are usually adjusted to achieve specific angles to ensure the cuts are accurate. Precise angle cuts are essential in metal fabrication since components need to fit at specific angles. Lastly, metal band saws are used in sculpting and artistic work. Artists and metalworkers use band saws to create detailed shapes, curves, and patterns in metal for sculptures and artistic installations. Metal band saws contribute to the artistic and creative process in metal artistry, allowing for the shaping and refinement of metal pieces with precision.

Features of metal band saws

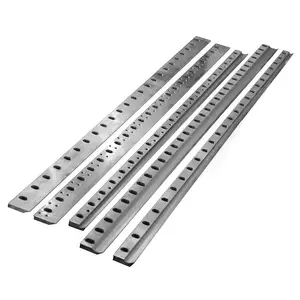

Metal band saws come with several features to enhance their functionality and precision. The first feature is the metal bandsaw blade size and type. Different blades are designed for specific materials and cutting applications. Therefore, one should choose a blade size based on the type and thickness of the metal. This allows for efficient cutting, and also the longevity of the metal band saw.

The other feature is the speed control. Most metal band saws offer different speed controls which allows operators to adjust the cutting speed based on the type and thickness of the metal. Having variable speed controls allows the band saw to handle different materials and cutting conditions. Another feature is the cooling systems. Most metal band saws often have a coolant system to lubricate and cool the blade during cutting. The coolant helps prevent blade overheating and prolongs blade life. Coolant systems vary, ranging from simple systems that use a coolant pump to more advanced systems with adjustable flow rates and misting capabilities.

Last is the safety features. Metal band saws should have safety features that protect the operator, especially during use. These safety features include emergency stop buttons, blade guards, blade breakage sensors, and tension indicators. Similarly, it's important for one to follow the safety guidelines and always use protective equipment when using a metal band saw.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4