LPG Cylinder Filling Plant Overview

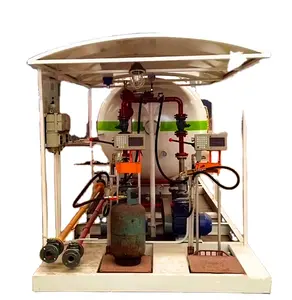

An LPG cylinder filling plant is a specialized facility designed for the safe and efficient filling of liquefied petroleum gas (LPG) into cylinders. These plants are integral to the distribution of LPG, a versatile fuel commonly used for heating, cooking, and industrial processes. The complexity of these plants varies, with options tailored to different scales of operation and technical requirements.

Types of LPG Cylinder Filling Systems

The variety of systems within an LPG gas refilling plant includes manual, semi-automatic, and fully automatic solutions. Manual systems are suitable for smaller operations, offering a cost-effective solution without the need for electricity. Semi-automatic and fully automatic systems cater to larger-scale needs, providing increased throughput and consistency in the filling process. Each system type ensures adherence to safety standards, which is paramount in handling LPG.

Applications and Features

LPG cylinder filling plants serve a multitude of sectors, including residential, commercial, and industrial markets. The equipment used in these plants is designed for handling high-viscosity substances and precise filling requirements. Features such as integrated weighing scales and automated shut-off mechanisms enhance both safety and efficiency.

Choosing the Right LPG Cylinder Filling Plant

Selecting an appropriate LPG cylinder filling plant cost-effective solution involves assessing production volume, space constraints, and specific industry needs. Factors such as the type of LPG cylinders, the required filling capacity, and the level of automation play a crucial role in this decision-making process.

Materials and Advantages

Materials used in the construction of an LPG cylinder filling plant are chosen for durability and compatibility with LPG. Stainless steel is commonly used for its corrosion resistance and strength. The advantages of utilizing a modern filling plant include improved productivity, enhanced safety, and the ability to meet high regulatory standards.

Streamlining Operations with LPG Cylinder Filling Plants

Incorporating an LPG gas refilling plant into your operations can significantly streamline the filling process. With advancements in technology, these plants offer sophisticated monitoring and control systems, ensuring accuracy and reducing the potential for human error.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4