A lincoln welder is a sophisticated piece of equipment designed for joining metals by applying heat generated through various welding processes. These machines are integral to industries where metal fabrication is essential. The lincoln welding machine is known for its reliability and versatility, catering to a wide range of welding tasks from simple home repairs to complex industrial constructions.

Types and Applications of Lincoln Welders

Lincoln welders encompass a variety of models, each with unique characteristics to suit different welding needs. The lincoln mig welder is prized for its ability to handle thin or thick materials with precision, making it ideal for auto body repair and construction. The lincoln electric welding machine often features multi-process capabilities, such as the lincoln multi process welder 210, which can perform stick, TIG, MIG, and flux-cored welding, offering versatility for fabricators who work with diverse materials and welding processes. The lincoln 210 mp welder is particularly favored in machinery repair shops and home use due to its adaptability and ease of use. These various types ensure that for every metal joining challenge, there is a Lincoln welder designed to meet it with precision and efficiency.

Structure and Features of Lincoln Welding Equipment

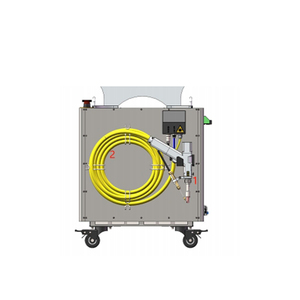

The structure of a lincoln welding machine is a marvel of engineering, designed to provide stability, durability, and ease of use. The physical components include a robust metal frame that houses the welding apparatus, control panels, and various connectors for different welding processes. For example, the power mig 210 features a user-friendly interface with push-and-turn digital controls and a color display that guides the user through setup. This machine, like many Lincoln welders, includes advanced options such as adjustable drive systems that help prevent wire tangling and crushing, and a patented split wire guide system that improves wire feeding. The integration of these components ensures that the welder operates smoothly, allowing for consistent, high-quality welds.

Materials and Durability of Lincoln Welding Machines

The materials used in lincoln welding equipment are selected for their resilience and thermal conductivity. High-grade aluminum, copper, and steel are commonly used in the construction of the welding machines. These materials are chosen for their ability to withstand high temperatures and their durability. For instance, the outer casing of the lincoln electric welder is often made of heavy-duty steel, which protects the internal components from damage and ensures the machine can endure the harsh conditions of a welding environment. The use of these materials contributes to the long service life Lincoln welders are known for.

Business Usages and Applications of Lincoln Welding Equipment

Lincoln welders are indispensable tools across various industries. In building material shops, the precision of a lincoln mig welding machine allows for the creation of high-quality joins that are essential for structural integrity. In construction, the portability and multiprocess capabilities of the lincoln power mig 210 mp enable workers to perform on-site repairs and installations with ease. Manufacturing plants utilize these welders for their consistent output and reliability, which are crucial for maintaining production schedules and quality standards. The versatility and efficiency of Lincoln welding machines create significant business value by enhancing productivity, reducing downtime, and ensuring the quality of the welds.

Functions and Capabilities of Lincoln Welding Machines

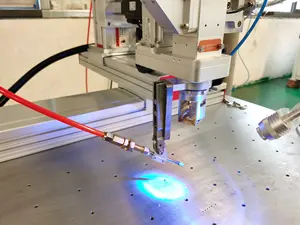

The primary function of a lincoln welding machine is to join metal parts with precision and strength. Specific tasks that these machines are designed to perform include creating clean, strong welds in various positions, controlling heat input to prevent metal warping, and allowing for the welding of different types of metals with a change of settings or wire types. The lincoln 210 mig welder, for instance, can switch between MIG and flux-cored welding, enabling users to work with a wider range of materials and thicknesses without the need for a separate machine.

Distinctive Features of Lincoln Welding Equipment

Lincoln welding machines are known for their innovative features that set them apart from competitors. The lincoln wire welder models often include advanced motor systems that provide precise control over the wire feed speed, greatly enhancing the quality of the weld. Many models also feature dual voltage inputs, allowing them to be used in various settings without the need for additional equipment. The lincoln welding shield and lincoln welding mask are designed with the latest safety technology to protect users from welding sparks and UV radiation, while also providing comfort for long periods of use.

Benefits and Improvements Offered by Lincoln Welders

Using a lincoln welder brings numerous benefits to the user. The machines are designed for ease of use, with intuitive interfaces that allow for quick setup and adjustments. This user-friendliness translates into reduced training time for staff and increased productivity. The reliability of a lincoln electric welding machine means fewer interruptions due to equipment failure, and the versatility of machines like the lincoln power mig 210 means that a single unit can be used for a variety of welding tasks, reducing the need for multiple machines.

How does a Lincoln welding machine ensure welding quality?

A lincoln welding machine ensures welding quality through its advanced control systems and precision engineering. The machines are designed to maintain a stable arc and consistent wire feed, which are critical for achieving strong and clean welds. The lincoln welding shield and lincoln welding mask provide safety without compromising on control, allowing for precise work even in challenging environments.

What kind of technical support does Lincoln offer?

Lincoln welder company offers extensive technical support, including online and video assistance. For more complex issues, overseas third-party support is available, ensuring that users of lincoln welding equipment can receive help regardless of their location. Additionally, the availability of engineers for overseas machinery service is a testament to the global reach and reliability of Lincoln's customer service.

Are Lincoln welders suitable for all types of metal fabrication?

Yes, lincoln welders are suitable for a wide range of metal fabrication tasks. The versatility of machines like the lincoln 210 mig welder and the lincoln wire welder allows them to be used on various materials, including carbon steel, stainless steel, and aluminum alloys. This makes them an ideal choice for businesses that work with diverse fabrication projects.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4