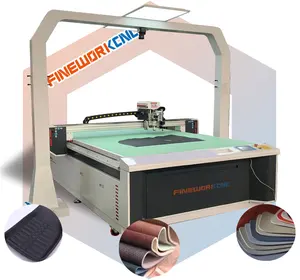

ZXT Full Automatic Digital Industrial CNC Genuine Garment Natural Leather Cutting Machine For Sale

Perforated Machine Steel Plate Punching Machine Punch Machine For Sheet Metal Hole Punching

Automatic Vibrating Knife Car Carpet Leather Upholstery Vibrating Cnc Knife Cutting Machine

Mineral Salt Block Press Machine Animal Salt Mineral Block Licking Making Press Machine With CE ISO

Metal Punching Machine Metal Sheet Perforated Machine Steel Plate Punching Machine

Leather Staking Machine For Cow Buffalo Sheep Skin Make The Leather Softener

High power leather perforating machine for leather with 2.2kw

CNC car seat leather hole machine leather perforating machine leather hole punching machine

leather car seat hole punching perforation machine

180 tons High Precision hydraulic Plane Leather Perforating Embossing Machine

Leather Embossing Machine hydraulic leather perforating machine

PYS Factory Price Wholesale Cost-effective leather perforating machine kabartma machine Suitable for non-woven fabric

CNC Leather Sewing Perforation Machine For Leather Car Seat Upholstery Car Interior

CNC Leather Sewing Perforation Machine For Leather Car Seat Upholstery Car Interior

automatic CNC car seat cover leather hole perforating punching machine

PU/PVC Leather Embossing/Plating/Polishing/Perforating Machine

CNC leather punching machine for shoe bag clothing industrial automatic leather perforation machine

GBOS hot needed fast speed leather perforating laser making machine

CNC Leather Sewing Perforation Machine For Leather Car Seat Upholstery Car Interior

Automatic CNC car seat cover leather hole perforating punching sewing machine

80Ton Leather Perforating Machine For Shoe&Bag Making

YT-609-120T Automatic shoe leather Patterns Hydraulic Perforating Embossing Pressing Machine

High speed leather perforating machine/perforated leather machine

Car Seat Perforated Leather Digital CNC Cutting Machine

AOYOO pineapple perforated leather tape hand operated clicker press cutting machine

automatic webbing ribbon pvc paper tube leather hole perforating punching cutting machine

High speed leather perforating machine/perforated leather machine

Leather Perforation Hole Goods Cutting Press Punching Machine For Belt Wallet Price

Richpeace Automatic Plate Mount Leather Perforation Machine For Car Seat Cover

Automatic Hydraulic Shoe Leather Patterns Perforating Leather Embossing Making Machine

1650 Leather Punching Leather Perforation Animal Skin Processing Machine

CNC Leather Sewing Perforation Machine For Leather Car Seat Upholstery Car Interior industrial sewing machine

Glory Tang car seat cover leather round hole perforated sheet punching machine for big size

Manufacturers direct sale cnc pvc leather perforated machine ventilated seat

bathbomb pneumatic door perforated sheet machine leather pneumatic door pressing punching machine

VCHI Galvo head Laser Cutting Machine180W perforated leather machine 120cuts wood engraving

Personalized PVC IMD IML perforation leather target hole punching machine for plastic panel

TC Advanced technology leather perforating machine cnc leather cutter leather die making machine With good after sales service

punching machine leather puncher professional perforator machine economy paper hole drilling machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4