A homogenizer is a versatile piece of equipment widely used in industrial and laboratory settings to create uniform mixtures from solid and liquid particles. Known by various names such as cell lysor, dispenser, high shear mixer, rotor stator homogenizer, or sonicator, its primary function is to reduce particle sizes to a range of 0.2 to 2 microns, achieving stable dispersions and emulsions. The process involves shredding, wetting, dissolving, emulsifying, extraction, precipitation, and cell rupture.

Homogenizers are categorized based on their valve configurations into single-stage and two-stage types, with the former using a single valve and the latter employing two valves. The homogenizing valve, a critical component, works in tandem with the valve seat to form the opening through which the fluid passes. The breaker ring, tension spring, and homogenizing pumps are other essential parts that contribute to the homogenization process.

The effectiveness of a homogenizer is grounded in three physical principles: shearing, turbulence, and cavitation. Shearing occurs as particles are caught between layers of fluid moving at different velocities, turbulence arises from high-velocity fluid motion creating eddy currents, and cavitation happens when pressure drops significantly within the fluid, forming vapor cavities that collapse and generate shock waves, further breaking down particles.

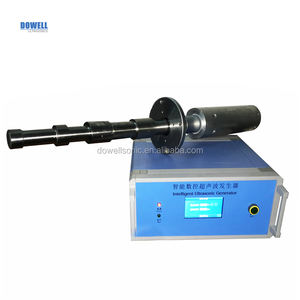

There are several types of homogenizers, each with specific advantages, making them suitable for particular applications. High-pressure homogenizers, mechanical homogenizers, including colloid mills and rotor-stator types, and ultrasonic homogenizers are some of the common varieties, each utilizing different mechanisms to achieve homogenization.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4