What are Grinding Equipment

Grinding equipment encompasses a wide array of machinery designed for the purpose of reducing the size of materials to a finer consistency. These machines, which play a vital role in numerous industries, are engineered to process a variety of substances ranging from grains in food production to ores in mining operations. By converting large, raw materials into smaller, more manageable particles or even powders, grinding equipment facilitates further processing or makes products ready for consumption or market sale.

The working principle of grinding equipment is founded on the application of mechanical forces that break down the material. This breakdown can be achieved through various mechanisms, including crushing, shearing, or abrasion. The choice of mechanism depends on the characteristics of the material being processed and the desired end product. For instance, softer materials may require less force and could be processed using machines that grind using abrasion or shear forces, while harder materials might need the application of compressive forces through crushing.

For businesses involved in sectors such as agriculture, food processing, pharmaceuticals, construction, and recycling, these machines are essential tools in their operations. They not only improve efficiency by speeding up production but also help in achieving consistency in product size and texture—a critical factor in many industrial processes.

Types of Grinding Equipment

The market offers an array of grinding equipment types designed to meet the specific needs of various applications and industries. Each type has its own unique features and is best suited for particular use cases:

Ball Mills: These common pieces of grinding equipment use spherical grinding media to break down materials by impact and attrition. They are widely used in mining for ore processing and in the production of paints, ceramics, and pyrotechnics.

Disc Mills: Equipped with one stationary and one rotating disc, disc mills are capable of fine grinding or even pulverizing various materials. They are often found in agricultural applications for grain milling or in food processing plants for spice grinding.

Attrition Mills: These mills employ a shearing action to grind soft or fibrous materials. They find common usage within the food industry for grinding grains and pulses and also within the chemical and pharmaceutical industries.

Jet Mills: Utilizing high-velocity air streams to cause particle-to-particle impact, jet mills are particularly effective for superfine grinding of dry powders. They are often employed when contamination from milling media must be avoided, such as in pharmaceutical applications.

Hammer Mills: Characterized by high-speed rotating hammers within a crushing chamber, hammer mills efficiently reduce the size of materials such as grains, spices, and biomass.

How to choose Grinding Equipment

Choosing the right grinding equipment for your business requires careful consideration of several factors:

Material Characteristics: The physical properties of the material you need to grind—such as hardness, abrasiveness, moisture content—will significantly influence the type of equipment best suited for your process.

Desired Particle Size: Different types of grinding equipment offer varying degrees of control over the final particle size. Mills that provide a wide range of particle size adjustments may be preferred if varied output sizes are necessary.

Throughput Requirements: The volume of material that needs to be processed within a given time frame will determine the size and power requirements of the equipment.

End-use Application: Consider where and how the ground material will be used. For instance, food-grade stainless steel construction might be necessary for food processing applications to meet hygiene standards.

Cost Considerations: Not just the initial purchase price but also ongoing operating costs such as energy consumption, maintenance expenses, and replacement parts should be factored into your decision-making process.

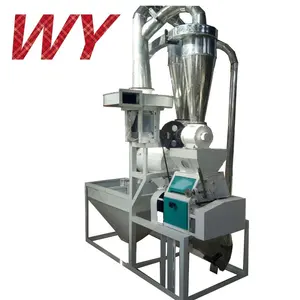

Best Grinding Equipment on Alibaba.com

Alibaba.com stands out as a premier destination for sourcing industrial machinery like grinding equipment. With its extensive global reach connecting buyers with suppliers from various parts of the world, Alibaba.com facilitates finding exactly what your business requires. Whether you're looking for specialized machinery that can handle unique raw materials or versatile grinders that can serve multiple functions within your operations, Alibaba.com's vast selection is bound to have options that align with your needs.

Suppliers on Alibaba.com offer machinery with key selling points such as ease of operation, multifunctionality, competitive pricing, and long service lifespans. From robust ball mills ideal for mineral ore processing to precision jet mills suitable for pharmaceutical applications—every imaginable type of grinding machine is available through this extensive marketplace. Furthermore, services like Trade Assurance provide an added layer of security by protecting payments until delivery is confirmed.

As you browse through Alibaba.com's offerings, you'll find that many suppliers provide comprehensive after-sales services including online support and technical assistance—a testament to their commitment to customer satisfaction. With tools that simplify communication and features that allow easy mobile access and language localization, Alibaba.com ensures that no matter where your business is located or what your specific requirements might be; you'll have a seamless experience finding and acquiring top-tier grinding equipment.

Common FAQs for Grinding Equipment

What types of grinding equipment are available for industrial use?

There are several types of grinding equipment available for industrial use, including ball mills, disc mills, attrition mills, jet mills, and hammer mills. Each type serves specific purposes and is suitable for different applications depending on material properties and desired particle size.

How do I determine the best type of grinding equipment for my application?

To determine the best type of grinding equipment for your application, you should consider the material's characteristics (hardness, abrasiveness, etc.), the desired particle size of the output, your throughput requirements, and the specific end-use application of the ground product.

Can grinding equipment handle both dry and wet materials?

Some grinding equipment is designed to handle either dry or wet materials, while others can accommodate both. It's important to choose a machine that is suitable for the moisture content of the materials you intend to process.

What factors should I consider when estimating the operating costs of grinding equipment?

Operating costs for grinding equipment include energy consumption, maintenance expenses, replacement parts, and labor. Evaluating these factors will give you a clearer understanding of the total cost of ownership.

Are there grinding machines suitable for food processing applications?

Yes, there are grinding machines specifically designed for food processing applications. These often feature food-grade stainless steel construction and meet certain hygiene standards necessary for food production.

What after-sales services are typically provided with the purchase of grinding equipment?

After-sales services can vary but may include online support, video technical assistance, field maintenance and repair services, and engineers available to service machinery overseas. It's vital to confirm what after-sales services are offered prior to purchase.

How does particle size adjustment work in different types of grinding equipment?

Particle size adjustment mechanisms vary across different types of grinding equipment. Ball mills may adjust particle size by changing the ball size or mill speed, while disc mills might allow gap adjustments between discs. It's important to choose a grinder that provides the level of control you need.

Can I find grinding equipment suited for small-scale production?

Yes, suppliers offer a range of grinding equipment suitable for both small-scale production and large industrial operations. You can select machinery based on your specific production volume requirements.

Is it possible to customize grinding equipment to fit my unique business needs?

Many suppliers on platforms like Alibaba.com can offer customized solutions based on your unique business requirements, including modifications to handle special materials or achieve specific production capacities.

How does Alibaba.com ensure the quality of grinding equipment sold on its platform?

While Alibaba.com connects buyers with suppliers and does not directly ensure product quality, it offers services like Trade Assurance which helps protect buyer payments until delivery is confirmed. Buyers are also encouraged to review supplier credentials and customer feedback before making a purchase.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4