What is Glue Roller Machine

Glue roller machines are specialized equipment designed for the application of adhesive materials in a controlled and uniform manner. They are essential tools in various industries, including printing, packaging, woodworking, and construction, where precise and consistent adhesive application is critical for product quality. These machines ensure that adhesives are applied evenly over large surface areas, providing a strong and durable bond between two or more materials.

The principle behind glue roller machines is relatively straightforward. A reservoir of adhesive, often in the form of a tank or tray, is placed beneath a roller or a series of rollers. The adhesive is then transferred onto a rotating roller that evenly distributes it onto the substrate as it turns. The roller's speed and pressure are typically adjustable to suit different types of adhesives and materials. This method of application is highly efficient, as it can cover a significant area with a uniform layer of glue in a short amount of time.

Glue roller machines are designed for professionals who require a high standard of adhesive application in their operations. Whether it's for large-scale production lines that create packaging materials or small-scale workshops that manufacture custom furniture pieces, these machines can greatly enhance productivity and the quality of the finished product. Their operation may involve manual control or be fully automated with various features such as pre-set programs, electronic controls, and sensors for measuring adhesive temperature and viscosity.

Types of Glue Roller Machines

There is a diverse range of glue roller machines available to suit various industrial applications. Each type is engineered with specific features that cater to different materials and tasks.

-

Hand Glue Rollers: These are compact and portable machines that are perfect for small-scale tasks or for use in hard-to-reach areas. They typically have a smaller roller size and can be used for localized application of adhesives.

-

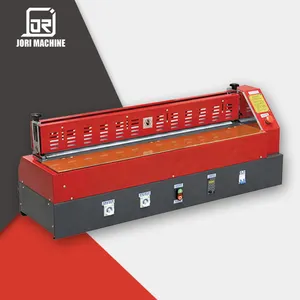

Automatic Glue Roller Machines: Designed for larger-scale applications, these machines feature multiple rollers and may include advanced features like digital controls, automatic glue application, and conveyor systems for industrial production lines.

-

Hot Melt Rollers: Utilizing hot melt adhesives, these machines are commonly used in the packaging industry for sealing boxes or applying labels. They heat the adhesive before application for better flow and adhesion.

-

Silicone Gel Applicators: A newer addition to the category, these machines use a roller system to apply silicone gel onto substrates. They are often used in electronics or automotive applications where thermal management is crucial.

-

Pressure Sensitive Adhesive (PSA) Roller Applicators: These machines apply pressure-sensitive adhesives, which are often used in labeling, tape application, or any process where the adhesive must be activated by pressure against the material.

How to choose Glue Roller Machine

Selecting the right Glue Roller Machine is crucial for businesses looking to optimize their production processes. When considering a purchase on Alibaba.com, it's important to assess several factors:

-

Material Compatibility: Choose a machine that is compatible with the specific type of material you will be using. Whether you're working with plywood, MDF, particleboard, or solid wood, ensure that the roller machine can apply the appropriate type of adhesive for proper bonding.

-

Production Volume: The quantity of items you need to glue consistently influences your choice. High-volume environments may require an automatic or conveyor-type machine to maintain efficiency.

-

Gule Quality: The quality of the glue used affects the strength and durability of the bond. Opt for machines that support high-quality adhesives designed for your industry's requirements.

-

Size of Items Being Glued: Consider the size of the items you'll be gluing. Ensure that the machine has adjustable rollers or settings that can accommodate a range of sizes, which will maximize its utility.

-

Available Space: The size of your facility and the layout of your production line will dictate whether you can accommodate a large conveyor-type machine or if you'll need something more compact like a desktop model.

By carefully evaluating these considerations in line with your specific needs and the types of products you manufacture or sell, you can make an informed decision when purchasing a Glue Roller Machine through Alibaba.com's extensive marketplace.

About Glue Roller Machine on Alibaba.com

Alibaba.com stands out as an expansive marketplace that connects businesses with a vast selection of glue roller machines suited for various industrial applications. Whether you're in manufacturing, construction, or retail, Alibaba.com offers access to a multitude of options from suppliers worldwide—allowing you to find a machine that meets your specific requirements without having to compromise on quality or functionality.

The platform's commitment to facilitating global trade is evident through features that support seamless transactions such as mobile-friendly buying processes and multilingual communication capabilities. Moreover, Alibaba.com's Trade Assurance service underscores its dedication to customer satisfaction by safeguarding payments until order fulfillment is confirmed.

In an era where convenience and reliability are paramount, Alibaba.com excels by providing not only an extensive range of products but also by ensuring that suppliers offer online trade solutions that cater to evolving business needs. This makes Alibaba.com not just a marketplace but a valuable partner in operational efficiency for businesses around the world.

Common FAQs for Glue Roller Machine

What is the primary use of a glue roller machine?

Glue roller machines are used to apply adhesive materials evenly and precisely onto surfaces, which is particularly useful in industries like packaging, woodworking, and in print finishing processes.

How does a glue roller machine work?

A glue roller machine typically uses a heated roller to melt and apply a layer of adhesive onto a material, ensuring a strong and consistent bond.

What types of adhesives can be used with a glue roller machine?

Glue roller machines can be used with a variety of adhesives, but it's important to select a machine with the appropriate temperature range and roller type to accommodate the specific adhesive used.

Can glue roller machines be used on all materials?

Glue roller machines are versatile, but the type of roller required will depend on the material you are working with. Some materials may require specific adhesive formulations for proper bonding.

Are there different sizes of glue roller machines available?

Yes, there are various sizes of glue roller machines to accommodate different production scales and operational needs.

What should I consider when choosing the material for the rollers of a glue roller machine?

When selecting the material for the rollers, consider the type of adhesives you will be using and the consistency of your materials, as different rollers may be better suited for certain adhesives.

How do I know if a glue roller machine is easy to operate?

Look for machines with user-friendly interfaces, such as touchscreen controls or digital temperature settings, and those that come with clear operational instructions.

Is it possible to get a machinery test report for a glue roller machine?

Yes, some suppliers provide machinery test reports. It's important to check with the supplier about this documentation to ensure the equipment meets industry standards.

What kind of maintenance does a glue roller machine require?

Regular maintenance is essential to ensure the longevity and performance of a glue roller machine. This may include cleaning the rollers, checking for any loose parts, and ensuring all moving parts are well lubricated.

Can I customize a glue roller machine according to my business needs?

Many suppliers on Alibaba.com offer customization options for their glue roller machines, such as roller width, type of adhesive used, additional features, and specific requirements.

Are there any safety considerations when operating a glue roller machine?

Always follow the manufacturer's safety guidelines and use personal protective equipment when operating a glue roller machine. This includes wearing safety glasses, gloves, and appropriate clothing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4