Furniture Manufacturing Machinery: An Overview

The realm of furniture manufacturing machinery encompasses a diverse array of equipment designed to meet the intricate demands of furniture production. This category includes a vast selection of machines, from furniture making machines that handle the initial stages of construction to furniture factory equipment that provides finishing touches to the final product.

Types of Furniture Manufacturing Machinery

In the furniture production industry, the machinery used is as varied as the items being crafted. Wooden furniture manufacturing machines are integral for businesses focusing on traditional and modern wooden furnishings, enabling precise cuts and detailed craftsmanship. For metal-based items, steel furniture manufacturing machines are indispensable, providing the strength needed to manipulate heavier materials. On the other hand, particle board furniture manufacturing machinery caters to the production of engineered wood products, a popular choice in contemporary furniture design.

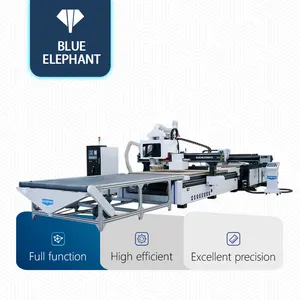

Applications and Features

The application of furniture manufacturing machinery spans across various production stages, from raw material processing to the final assembly. Machines like the cabinet maker machinery are tailored for creating detailed cabinetry with precision. The versatility of these machines is evident in their adjustable settings and interchangeable cutting bits, which allow for a wide range of operations, from simple cuts to complex joinery.

Materials and Advantages

The construction of furniture manufacturing machinery involves robust materials that withstand the rigors of heavy usage. Stainless steel components are common in stainless steel furniture making machines, ensuring longevity and consistent performance. The ergonomic design of these machines offers enhanced comfort and safety, reducing the risk of operator fatigue and accidents during long hours of operation.

Choosing the Right Machinery

Selecting the appropriate furniture manufacturing machinery is crucial for achieving desired outcomes. Factors such as throughput rates, table configuration, and power rating play significant roles in determining the efficiency of furniture factory machines. For specialized tasks, such as bending metal for storage solutions, the almirah bending machine price and specifications are key considerations for businesses looking to invest in such equipment.

Ensuring Versatility and Durability

Durability is a cornerstone of furniture manufacturing machinery, with many machines boasting long service lives due to their high-quality construction. The adaptability of machinery required for furniture manufacturing is also a critical feature, allowing woodworkers to expand their creative horizons and operational capacity. Whether it's crafting intricate designs or mass-producing standard furniture pieces, the right machinery can significantly enhance productivity and craftsmanship.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4