Understanding Fractional Distillation Columns

Fractional distillation is a pivotal process in separating complex mixtures into their individual components, and the fractional distillation column is at the heart of this operation. This apparatus is essential in industries ranging from petrochemical to beverage production, where precision and efficiency are paramount. The design of a fractional distillation tower is sophisticated, allowing for the separation of mixtures based on differences in their boiling points.

Types and Applications of Fractionating Columns

There are various types of fractionating columns used across industries. The vigreux fractionating column, with its intricate design, is widely used in laboratories for detailed separation work. On the other hand, a fractionating column for crude oil is built for the heavy-duty separation of hydrocarbon fractions in the petrochemical industry. Each type serves the specific needs of different applications, from the delicate separation of essential oils to the robust needs of crude oil refinement.

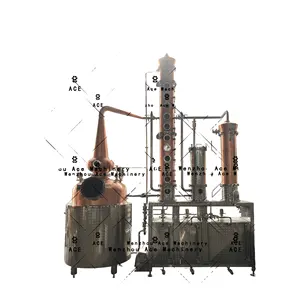

Features and Materials of Fractional Distillation Equipment

The construction of a fractional distillation column is a testament to modern engineering. Materials like stainless steel are commonly used, providing corrosion resistance and durability. A glass fractionating column offers transparency for monitoring the distillation process, while a fractional distillation chamber ensures the controlled environment necessary for precise separations. Features such as the partial condenser distillation column enhance the efficiency of the distillation by allowing selective condensation of vapors.

Advantages of Using a Fractionating Tower

Utilizing a fractionating tower crude oil or for other mixtures offers numerous advantages. The efficiency of these columns lies in their ability to separate complex mixtures into pure components, which is crucial for quality control and production standards. The adaptability of fractionating column types means they can be tailored to specific processes, optimizing performance and output.

Selecting the Right Fractionating Column

Choosing the appropriate fractionating column in fractional distillation is vital for achieving desired results. Factors such as the nature of the mixture, the required purity levels of the separated components, and the scale of operation dictate the selection process. While a simple distillation column might suffice for less complex tasks, a more sophisticated fractional distillation fractionating column might be necessary for intricate separations.

Conclusion

In conclusion, the fractional distillation column is a cornerstone in the separation industry, offering versatility and precision. Alibaba.com, as a leading B2B platform, connects buyers with a diverse range of suppliers offering these sophisticated pieces of equipment. By understanding the intricacies of these systems, businesses can make informed decisions to meet their operational needs without the hassle of navigating through countless vendors.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4