A foam injection machine is an advanced apparatus engineered for the precise and controlled dispensing of polyurethane foam, widely utilized across various sectors including insulation and packaging. These machines play a crucial role in industries that demand efficient foam production for their goods or services. Offering a plethora of features, foam injection machines meet a diverse array of commercial requirements, guaranteeing that each use case is matched with the appropriate foam consistency and caliber.

Types and Characteristics of Foam Injection Machines

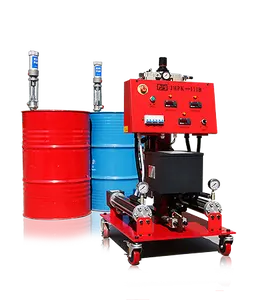

The foam injection machine category includes a range of models, each distinguished by its features to fulfill distinct functions. For example, the double barrel components mini PU foam machine is designed for precise concrete repair and grouting in smaller operations. Conversely, portable PU injection machines prioritize transportability, facilitating insulation work across various sites with relative ease. Low-pressure small PU foam machines are ideal for cushion packaging, delivering a soft yet effective injection to safeguard fragile items in transit. Each variant is engineered to overcome particular industry challenges, be it the necessity for mobility, exactitude, or delicate material handling.

Structure and Operation of Foam Injection Machines

The intricate design of a foam injection machine is a testament to modern engineering, incorporating several vital components that function harmoniously. At its heart lies a motor that energizes the system, a PLC for operational control, and a powerful engine that propels the injection mechanism. The pressure vessel serves as the storage for the foam material under pressure prior to injection, while the gearbox ensures the seamless transfer of mechanical power. The pump is essential for circulating the foam material throughout the system, and premium bearings guarantee the smooth operation of all moving parts. These elements coalesce to form a sophisticated and reliable machine capable of executing tasks with precision.

Materials and Properties in Foam Injection Machines

The construction of a foam injection machine utilizes materials selected for their robustness and efficacy. High-grade steel is typically employed for the frame and structural parts, owing to its durability and resilience. The plastics processed by the machine, such as PA, PE, and LDPE, are chosen for their capacity to yield foams of varying densities and characteristics. These substances are preferred for their toughness, adaptability, and suitability with the foam injection process, ensuring that the final product adheres to the necessary standards and specifications.

Business Usages and Applications

Foam injection machines are indispensable across a multitude of commercial environments. Within the construction realm, they provide insulation for edifices and mend concrete, bolstering structural soundness and thermal efficiency. In the manufacturing domain, these machines are crucial for creating protective cushioning for merchandise, pivotal for secure transport. Retail enterprises employ foam for packaging, illustrating the machine's adaptability in shielding an extensive array of items. Each use case not only underscores the machine's practicality but also its ability to enhance business value by elevating product safety, quality, and endurance.

Functions and Tasks of Foam Injection Machines

The principal role of a foam injection machine is to infuse foam into an assortment of materials and products. This encompasses duties such as filling voids for insulation, supplying padding for packaging, and reinforcing structures via concrete restoration. The machine's design facilitates meticulous control over the foam's density and spread, ensuring it can undertake a wide array of tasks tailored to the particular demands of each application.

Features and Unique Selling Points

Notable attributes of a foam injection machine include its operational efficiency and the fully hydraulic system, which allow for optimal performance with minimal energy dissipation. Distinctive selling points like remote control functionality and high-pressure injection distinguish these machines from their rivals, providing users with exceptional command and excellence in foam output. The straightforward maintenance and extended lifespan are additional benefits that enhance the machine's allure in the marketplace.

Benefits and Positive Outcomes

The advantages of deploying a foam injection machine are numerous. Operators witness a surge in productivity due to the machine's precision and versatility. The prolonged lifespan and energy-conserving attributes offer financial benefits over the long term. Moreover, the superior foam produced complies with rigorous industry criteria, ensuring that the end products are secure, dependable, and perform effectively for their intended purposes.

How to Use and Maintain Foam Injection Machines

Proficient operation of a foam injection machine necessitates a thorough grasp of its controls and capabilities. Essential maintenance includes monitoring the motor, PLC, and pump for signs of wear or failure. Cleansing the pressure vessel and gearbox can avert accumulations that might impede functionality. Adhering to the manufacturer's instructions during installation is crucial to ensure the machine is configured correctly, which is vital for its safe and effective use.

How to Choose the Right Foam Injection Machine?

Choosing the suitable foam injection machine involves a deliberate evaluation of the machine's voltage, automation features, and material compatibility. Reviewing the machinery test report can shed light on the machine's performance and dependability. Furthermore, considering the availability of after-sales services can provide assurance of ongoing support when necessary.

How to Ensure High-Quality Foam Production?

To secure high-quality foam output, it is essential to select a foam injection machine outfitted with features that ensure clean operation and high efficiency. The machine should be adept at handling the specific plastics processed and should offer a significant level of safety to protect operators while maintaining consistent production standards.

What After-Sales Services Are Available?

Following the acquisition of a foam injection machine, purchasers can anticipate extensive after-sales services. These may encompass online assistance, video technical support, and the provision of engineers capable of servicing machinery abroad. Such services guarantee the machine's continued optimal performance and that any operational challenges are resolved swiftly and proficiently.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4