Introduction to Fluidized Bed Jet Mills

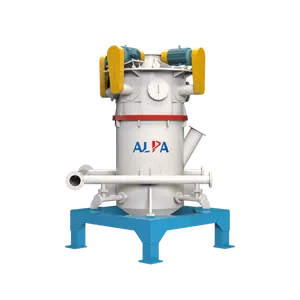

The fluidized bed jet mill is a pivotal piece of equipment in the realm of particle size reduction. Utilizing the principles of fluid mechanics, these mills employ a high-velocity stream of air to grind and classify particles simultaneously. The versatility of this milling technology makes it suitable for a broad range of materials, particularly those sensitive to heat and prone to contamination when processed by conventional grinding methods.

Types and Applications

There are several variations of jet mills, including the fluidized bed opposed jet mill and the opposed jet mill. Each type is tailored for specific applications, ranging from pharmaceuticals to ceramics. The fluidised bed opposed jet mill is particularly renowned for its efficiency in fine and ultra-fine particle size reduction, making it a preferred choice in industries where precision is paramount.

Operational Features

The operational features of a fluidized bed jet mill are designed to meet the rigorous demands of modern industry. The mill's grinding chamber allows for the expansion and circulation of air or inert gas, which is then accelerated through strategically placed nozzles. This process leads to particle collision and subsequent particle size reduction without the need for any moving mechanical parts, thus reducing wear and maintenance requirements.

Material and Design Advantages

The construction materials of a jet mill are chosen for their durability and resistance to wear. The design of a fluidized bed jet mill focuses on creating a consistent and controllable particle size distribution, which is crucial for many high-precision manufacturing processes. The absence of mechanical parts in the grinding zone minimizes contamination, making it suitable for processing pure, high-grade materials.

Choosing the Right Mill

Selecting the appropriate fluidized bed jet mill involves considering the specific particle size reduction requirements, material characteristics, and desired throughput. Suppliers on Alibaba.com can assist in identifying the most compatible mill variant for a given application, ensuring that the equipment aligns with the operational goals and material specifications.

Accessories and Parts

In addition to the core milling equipment, a range of replacement parts and accessories are available to support the ongoing efficiency of the fluidized bed jet mill. From nozzles and liners to classifiers and feed systems, these components are crucial for maintaining the performance and extending the lifespan of the milling equipment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4