An exhaust fan cover is an essential component in maintaining the functionality and safety of exhaust fans across various industries. These covers are designed to protect the fan blades from external debris, prevent accidents, and also contribute to the overall aesthetic of the equipment. With a focus on utility and durability, exhaust fan covers are tailored to meet the rigorous demands of their application environments.

Types and Characteristics of Exhaust Fan Covers

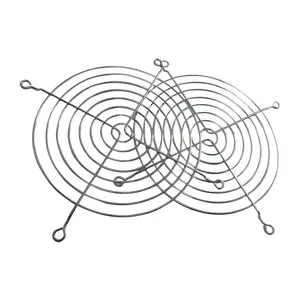

Exhaust fan covers come in various types, each serving specific functions and environments. The 300mm Series Axial Flow Exhaust Fan Cover is designed for industrial applications, providing robust protection and ensuring efficient airflow. The magnetic exhaust fan cover is another innovative type, utilizing magnetic fields to secure the cover in place, which is particularly useful in environments where quick removal and attachment are beneficial. The fan net cover, often made of a metal grid, is a common choice for general applications, providing a balance between protection and airflow. In addition to these, there are covers designed for specific fan sizes, such as the 120mm covers for smaller fans, and customized options for non-standard sizes, ensuring that every fan, regardless of its dimensions, can be adequately protected.

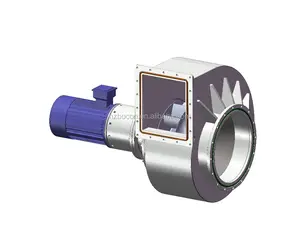

Structure and Operation of Exhaust Fan Covers

The structure of an exhaust fan cover typically includes a frame that supports a mesh or grille designed to prevent the ingress of debris while allowing air to pass through. Some covers also feature a hinged or removable section to facilitate easy access for maintenance. The operation of the cover in conjunction with the fan involves a synergy where the cover does not impede the fan's performance but enhances it by preventing the accumulation of debris on the fan blades. The components such as the raw water tank, heater, evaporator, condenser, and collector work in unison to ensure that the cover fulfills its role without disrupting the fan's function.

Materials and Properties

The materials used in exhaust fan covers, such as stainless steel, aluminum, and ABS, are selected for their durability and environmental resistance. Stainless steel is chosen for its strength and resistance to rust, making it ideal for high-humidity environments. Aluminum, being lightweight, is easy to install and provides good durability. ABS plastic offers a balance between cost-effectiveness and performance, with enough resilience to protect against impacts. The choice of material often depends on the specific application and the environmental conditions the cover will face. For instance, in coastal areas or chemical plants where corrosive elements are present, stainless steel would be the preferred material due to its superior corrosion resistance.

Business Usages and Applications

In manufacturing plants and machinery repair shops, exhaust fan covers are crucial for preventing occupational hazards and maintaining machinery integrity. In the construction industry, they protect fans from the pervasive dust. Retail and building material shops use them to ensure a clean environment for customers and products alike. These covers contribute to business value by reducing maintenance costs, prolonging equipment life, and ensuring compliance with safety regulations. In settings like electronics manufacturing, where dust can lead to product defects, fan covers play a critical role in quality control by minimizing airborne contaminants.

Functions of Exhaust Fan Covers

The primary function of an exhaust fan cover is to shield the fan and its components from external elements while allowing for unobstructed air flow. They also serve to prevent any accidental contact with the fan blades, ensuring a safer working environment. Additionally, these covers can be equipped with noise-reduction features to minimize the sound emitted by the fan during operation. Some covers are designed with a focus on enhancing the aesthetic appeal of the fan setup, offering a range of colors and finishes that can complement the design of the space where they are installed.

Features and Unique Selling Points

Exhaust fan covers are designed with features that set them apart, such as high efficiency in maintaining airflow, corrosion resistance for longevity, and waterproof and dustproof capabilities for protection in various environments. The availability of customized sizes and colors allows these covers to meet specific aesthetic and functional requirements, providing a competitive edge in the market. Advanced features may include integrated sensors to detect blockages or changes in airflow, which can be crucial for automated systems that require constant monitoring.

Benefits and Positive Outcomes

The benefits of using an exhaust fan cover include enhanced safety, protection of equipment from premature wear, and maintenance of air quality. These covers also contribute to energy efficiency by ensuring that fans are not overworked due to blockages, leading to lower energy consumption and cost savings. The psychological comfort provided by a well-protected fan system cannot be understated, as workers in industrial settings can operate with the assurance that safety measures are in place.

How to Use and Maintain Exhaust Fan Covers

Effective operation of an exhaust fan cover involves regular inspection to ensure that it is free from damage and securely attached. Choosing the right model requires consideration of the fan size, environment, and specific needs such as noise reduction or ease of removal. Cleaning involves a gentle wiping or vacuuming to remove dust, while maintenance may include checking for corrosion or wear. Installation should follow the manufacturer's guidelines to ensure a secure fit without impeding the fan's operation. For maintenance, it is recommended to establish a routine schedule, depending on the environmental conditions, to ensure that the covers remain in optimal condition.

Target Audience and Meeting Needs

The target audience for exhaust fan covers includes businesses in sectors like manufacturing, construction, and retail, where fan systems are integral to operations. The design and features of these covers are tailored to meet the specific needs of these industries, such as durability in harsh environments, ease of maintenance for high-usage areas, and aesthetic considerations for customer-facing settings. The covers are also beneficial for businesses looking to enhance their green credentials by reducing energy consumption through improved fan efficiency.

How does an exhaust fan cover enhance safety and efficiency?

An exhaust fan cover not only prevents debris from entering the fan but also minimizes the risk of injury by acting as a barrier between moving parts and the external environment. This safety feature is critical in workplaces to comply with health and safety regulations. Moreover, by reducing the ingress of particles, the cover ensures that the fan operates at optimal efficiency, without the airflow being obstructed.

What considerations should be made when selecting an exhaust fan cover?

When choosing an exhaust fan cover, it is important to consider the size and compatibility with the existing fan setup. The environment in which the fan operates should dictate the material selection, ensuring that the cover can withstand the conditions without corroding or degrading. Additionally, the ease of installation and maintenance should be evaluated to ensure that the cover can be managed without requiring excessive downtime.

How can a business ensure they are getting a high-quality exhaust fan cover?

To ensure a high-quality exhaust fan cover, businesses should look for products with a proven track record of durability and efficiency. Verifying the materials used, the manufacturing processes, and the quality control measures in place are essential steps. Engaging with suppliers on Alibaba.com who offer ODM and OBM services can also provide an additional layer of assurance that the product is designed to meet specific industry standards and requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4