An engine boring machine is a critical tool in the mechanical industry. It is specifically designed to bore holes in engine blocks. These machines are necessary for either repairing or rebuilding engines. This piece of equipment is an essential element in automotive shops, marine repair facilities, and in the manufacturing of new engines.

Types of engine boring machines

There are several types of engine boring machines available. For instance, the engine block boring machine is designed to create precise holes in the engine block for new cylinders. On the other hand, the engine cylinder boring machine is used to increase the diameter of the existing cylinders in an engine block, a procedure often necessary during engine overhauls. Another type is the motorcycle cylinder boring machine, which is specifically designed for boring cylinders in motorcycle engines. Each type of machine has its unique features and is suitable for specific tasks, depending on the engine's requirements.

Features of engine boring machines

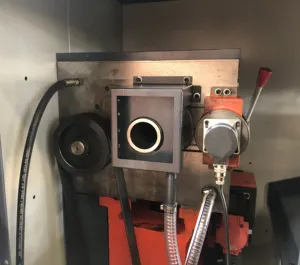

Engine boring machines come with various features that enhance their performance and usability. An important feature is the engine boring tool. This tool is the actual cutting device that bores the hole into the engine block. The accuracy and durability of this tool are instrumental in ensuring the precision of the bore.

Another key feature is the engine boring bar. The boring bar holds the cutting tool and ensures it moves in a straight line while cutting. It's designed to resist deflection, ensuring that the hole bored is perfectly straight. Some other features include adjustable speed controls and precision measurement systems, which ensure accurate and efficient operation.

Materials used in engine boring machines

The materials used in the construction of engine boring machines significantly contribute to their durability and efficiency. High-grade steel is commonly used in the manufacture of the main components of these machines, such as the boring bar for engine and the boring cylinder machine. Steel is preferred due to its strength and durability, which is necessary for handling the high-stress operations of boring engines.

An engine boring machine is a vital tool in engine repair and manufacturing. Its types are diverse, each designed for specific applications. The features of these machines, such as the engine boring tool and the engine boring bar, ensure their efficient operation, while the materials used in their manufacture provides their durability. Whether it's boring a engine block or enlarging a cylinder in an existing engine, the engine boring machine is an indispensable tool in the mechanical industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4