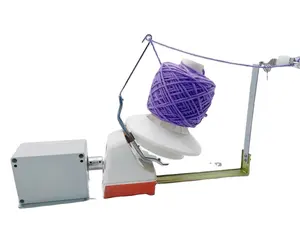

An electric yarn winder is a handy tool used by knitters and crocheters to wind yarn into neat and organized yarn cakes or balls. It automates the yarn winding process, making it faster and more efficient compared to manual winding.

Features of an Electric Yarn Winder

Electric yarn ball winders are equipped with an electric motor that powers the winding mechanism. This eliminates the need for manual turning, making the winding process quicker and less tiring. Knitters can now easily knit or crotchet without worrying about their yarn ball tangling or spiraling out of control. The motorized operation enables swift and efficient winding, saving time and effort for yarn enthusiasts who work with large quantities of yarn. Electric yarn winders can often accommodate a range of skein sizes and types, allowing users to wind various yarn weights and lengths.

Some electric ball winders feature a built-in cone holder, while others may come with a detachable cone holder. The cone holder keeps the yarn in place during winding. Tension control mechanisms help maintain an even and consistent winding pattern. This is especially important for preventing yarn tangling and ensuring a smooth winding process. Quality electric yarn winders are designed to operate quietly, allowing users to wind yarn without creating excessive noise. While electric yarn winders are generally compact, some models are designed to be portable, making them easy to move around or take to knitting and crochet gatherings. Automatic yarn ball winders are user-friendly, with straightforward controls and easy setup. They are suitable for both beginners and experienced yarn crafters.

Operating an Electric Yarn Winding Machine

Place the electric yarn winding machine on a stable and flat surface. After that, ensure that the machine is securely positioned to prevent movement during operation. Plug in the automatic yarn winding machine and turn on the power using the designated switch or button. Begin by attaching the end of the yarn to the machine. This is typically done by threading the yarn through a yarn guide or tension disc. Many automatic yarn winders have a tension adjustment mechanism. Set the tension to an appropriate level based on the type and thickness of the yarn being wound.

Next, guide the yarn through the winding guide or yarn guide on the machine. This ensures that the yarn follows a smooth path during winding. Activate the winding system. This is typically done by pressing a start button or engaging a foot pedal, depending on the machine's design. Keep an eye on the winding process to ensure that the yarn is winding evenly onto the cone or into a cake or ball. If any issues arise, such as tangling or uneven winding, pause the machine and treat the problem. Once the winding is complete, use scissors to cut the yarn from the machine. Tie a secure knot to prevent unraveling. Carefully remove the wound yarn cake or ball from the machine, ensuring that it is securely wound and organized. After completing the winding process, turn off the machine and unplug it for safety.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4