The Concept of Precision EDM Machines

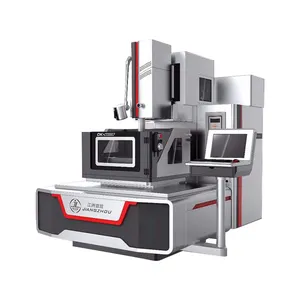

Precision EDM machines, also referred to as Electrical Discharge Machines, are sophisticated machining tools that employ electrical discharge machining to precisely shape and cut materials. These machines play a crucial role in industries requiring intricate and accurate operations, such as the manufacturing of precision metal components, electronics, and medical instruments. At the core of precision EDM is the controlled erosion of material through electrical discharges, enabling the creation of highly detailed and precise parts.

The operation of precision EDM machines involves passing an electrical current through the material being machined, leading to the formation of a plasma-like state in the gap between the electrode and the workpiece. This process generates repetitive sparks that melt and vaporize the material, resulting in exceptionally fine and controlled cuts. Equipped with a tool head typically crafted from copper or graphite, the machine directs the electrical discharge to remove material accurately. Maintaining a precise gap between the electrode and the workpiece ensures consistent and precise cuts.

These machines are specifically designed for professionals who demand high levels of accuracy and reliability in their work, such as toolmakers, mold manufacturers, and producers of precision parts. The technology underpinning precision EDM machines enables the attainment of intricate geometries and tight tolerances, which are essential in industries where components must fit perfectly or meet stringent performance criteria.

Varieties of Precision EDM Machines

Within the realm of manufacturing, various types of precision EDM machines cater to distinct tasks and materials:

-

Wire EDM Machines: These machines are tailored for cutting using a thin wire electrode, commonly used for crafting detailed shapes and fine features in metal parts, crucial for tool and mold production.

-

Sinker EDM Machines: Utilizing a vertical electrode, this type facilitates a plunge cut into a workpiece, typically employed in creating molds and dies with square or rectangular cavities and a smooth finish.

-

Drill EDM Machines: Equipped with rotating electrodes, these machines drill precise holes in workpieces, useful for achieving accurate holes in complex components.

-

Portable EDM Machines: Compact and designed for on-site use, these machines enable localized machining of electrically conductive materials without extensive setup, ideal for tool maintenance or mold adjustments on-site or at a client's premises.

Each machine type offers distinct advantages based on the project's requirements.

Selecting the Right Precision EDM Machine

When choosing a precision EDM machine for your business needs from Alibaba.com, several factors must align with your specific applications and production demands. The selection process heavily hinges on the material of the workpiece, desired surface finish quality, and required production volume.

For businesses working with hard metals or necessitating high-precision machining with superior surface finishes, sinker EDM machines may be the most suitable due to their capability to handle complex geometries. Conversely, for operations involving soft, highly conductive materials that demand high precision, wire EDM machines would be more fitting.

The size and complexity of your workpieces will also impact your decision; larger workpieces may require a sturdier machine with higher power output for efficient machining. Additionally, consider post-sale support services like online technical assistance or field maintenance provided by suppliers on Alibaba.com.

About Precision EDM Machines on Alibaba.com

Alibaba.com serves as a global marketplace linking buyers with suppliers offering a wide range of precision EDM machines tailored to diverse industrial needs. With over two decades of experience facilitating B2B transactions across sectors such as manufacturing, construction, and retail, Alibaba.com has emerged as a vital resource for businesses seeking specialized equipment like precision EDM machines.

The platform's extensive selection enables buyers to discover machines suited to their specific requirements, from local service availability to key features like high precision and user-friendliness. With mobile purchasing capabilities and multilingual communication tools, Alibaba.com ensures that businesses worldwide can efficiently procure the necessary machinery without constraints of location or language barriers.

Furthermore, Alibaba.com's commitment to secure trading experiences is evident through services like Trade Assurance, safeguarding payments until successful delivery. This dedication to reliability and customer satisfaction underscores why many consider it the premier platform for acquiring commercial-grade precision EDM machines meeting diverse operational needs while upholding quality and dependability.

Frequently Asked Questions about Precision EDM Machines

Primary Use of Precision EDM Machine

Precision EDM Machines are primarily employed for high-precision machining of intricate shapes challenging to produce using traditional cutting methods. They find common applications in industries like aerospace, automotive, medical, and tool manufacturing.

Operation of Precision EDM Machine

Precision EDM Machines utilize electrical discharges to erode conductive materials like metal. By delivering rapid pulses through a wire, these machines remove material with precision and minimal waste.

Materials Compatible with Precision EDM Machine

Precision EDM Machines can work with a broad array of conductive materials, including aluminum, hardened metals, stainless steel, and various alloys. However, the machine's specific capabilities will be influenced by its model and settings.

Micro Machining Capabilities of Precision EDM Machine

Indeed, specific models of Precision EDM Machines are explicitly designed for micro machining, capable of handling small workpieces with intricate details.

Common Products Manufactured with Precision EDM Machine

Precision EDM Machines are instrumental in producing diverse products such as medical devices, industrial molds, aerospace components, intricate electronic parts, and high-performance tools and machinery.

Considerations for Choosing a Precision EDM Machine

Key considerations include maximum workpiece size, material hardness, required tolerances, electrode material, material removal speed, and the machine's CNC control system.

Variety of Electrodes in Precision EDM Machines

Precision EDM Machines utilize various electrodes like copper, graphite, and brass, with the choice dependent on the application's needs.

Significance of Accuracy Rating in Precision EDM Machine

The accuracy rating plays a pivotal role in Precision EDM Machines as it directly impacts the quality of the workpieces produced. Typically measured in microns, the desired accuracy varies based on the machine's specifications.

Customization Options for Precision EDM Machine

Many suppliers offer customized services such as ODM or OEM, enabling businesses to tailor the machine's specifications to their specific requirements.

After-Sales Support for Precision EDM Machine

After-sales services may encompass online support, video technical assistance, field maintenance and repair services, and availability of engineers for servicing machinery internationally, contingent on the supplier's offerings.

Maintenance Requirements for Precision EDM Machine

Regular upkeep for a Precision EDM Machine includes cleaning, lubricating moving parts, inspecting and replacing filters as needed, and ensuring the cooling system operates efficiently.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4