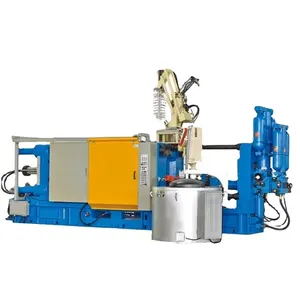

The die casting machine is an essential piece of equipment in the manufacturing industry. It is used to produce metal parts by forcing molten metal under high pressure into a die cavity. The metal then hardens rapidly to form a net-shaped component that is then ejected from the die.

Types of die casting machines

There are several types of die casting machines on the market. Some common ones are the cold chamber die casting machine and the hot chamber die casting machine. The type of machine used depends on the metal being cast. For instance, the cold chamber machine is typically used for metals with high melting temperatures such as aluminum and copper, while the hot chamber machine is used for metals with low melting temperatures such as zinc, lead, and magnesium. Another type of die casting machine is the gravity casting machine. Unlike the cold and hot chamber machines which use high pressure to force the molten metal into the die, the gravity casting machine uses the force of gravity to fill the die with molten metal.

Features of die casting machines

Die casting machines come with a variety of features designed to enhance their performance and efficiency. One key feature is the ability to control the speed and pressure of the injection process. This allows for precise control over the casting process, resulting in parts with high dimensional accuracy and low porosity. Another feature of die casting machines is the use of die clamps. These are used to hold the two halves of the die together during the casting process. Die clamps ensure that the die halves align correctly and remain closed under the high pressure of the injection process. Modern die casting machines also come with advanced automation features. These include automatic die lubrication systems, automatic metal ladling systems, and automatic part ejection systems. These automation features not only increase the productivity of the die casting process but also enhance the safety of the operation.

Materials used in die casting machines

Die casting machines are typically made from robust materials capable of withstanding the high pressures and temperatures involved in the die casting process. The machine frame is usually made from heavy-duty steel or cast iron, while the die itself is typically made from tool steel or tungsten carbide. The choice of material for the die is crucial as it determines the quality of the cast parts and the lifespan of the die. Tool steel dies are commonly used for casting aluminum and zinc parts, while tungsten carbide dies are used for casting harder metals such as copper and steel.

The die casting machine is a sophisticated piece of equipment with a wide range of applications in the manufacturing industry. It comes in various types and features, each designed to meet specific casting needs. The materials used in its construction are carefully chosen to ensure its durability and performance. Therefore, when considering the die casting machine price, it is essential to take into account these factors.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4