Understanding Crusher Jaw Plates

Crusher jaw plates are pivotal components of jaw crushers, which are widely utilized in various industrial applications for the size reduction of rocks, ores, and other solid materials. These plates provide the crushing action by acting as a pivot point and crushing the material in between, making them indispensable in the mining, construction, and demolition industries.

Types and Applications of Jaw Plates

The jaw plate for crusher comes in different types, each designed to suit various operational requirements. The toggle plate jaw crusher and fixed jaw plate are commonly used in the industry, serving different purposes like adjusting the discharge size and providing protection from uncrushable material, respectively. Applications range from mining operations, where stone crusher jaw plate models are used to break down ores, to construction and demolition sites where concrete and other materials are crushed for reuse or disposal.

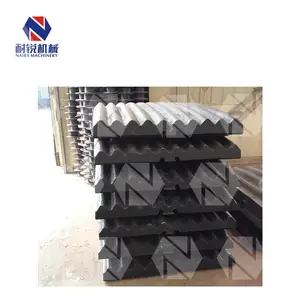

Features and Materials

A crusher plate must withstand significant wear and tear. Hence, materials like manganese steel are often used for their durability and resistance to abrasion. The crusher wear plates are also designed with specific thickness and profiles to maximize lifespan and performance. The swing jaw plate and movable jaw plate are engineered to facilitate efficient crushing movements within the crusher.

Advantages of Optimal Jaw Plates

Selecting the appropriate jaw crusher side plate or crusher liner plate can lead to improved material flow, reduced downtime, and a more cost-effective crushing process. An optimally designed jaw crusher cheek plates can also ensure finer crushing granularity and a more uniform particle size distribution, enhancing the overall efficiency of the crushing operation.

Choosing the Right Jaw Plates

When selecting a jaw crusher plate, it is crucial to consider the material's hardness and abrasiveness, as well as the crusher's size and operational parameters. The jaw plate material and design should match the application to ensure optimal performance. While Alibaba.com does not endorse specific products, the platform offers a diverse range of options to cater to various industrial needs.

Conclusion

In conclusion, crusher jaw plates are essential components of jaw crushers, playing a significant role in industrial material processing. Alibaba.com's extensive catalog provides a platform for buyers to explore a variety of options, ensuring they can find the right fit for their specific requirements without direct endorsements or promotional claims.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4