Introduction to Cotton Carding Machines

The cotton carding machine is a pivotal instrument in the textile industry, playing a crucial role in the cotton carding process. This machinery is designed to clean cotton fibers, detangle them, and align them to produce a continuous web or sliver suitable for subsequent processing. Understanding the mechanics and applications of these machines is essential for those involved in the production of cotton textiles.

Types of Cotton Carding Machines

There are primarily two types of carding machines utilized in the industry: the flat card and the roller card. Flat carding machines are more commonly associated with processing short-staple fibers, often used in the production of synthetic fibers. In contrast, roller cards are adept at handling longer fibers, making them suitable for longer-staple cotton. Each type of cotton carding machine is engineered to cater to specific material types and production demands, ensuring the versatility of the carding process.

Features and Applications

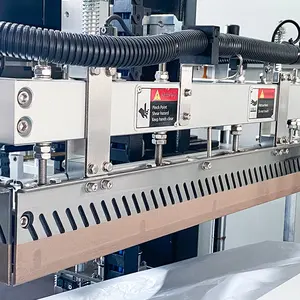

The carding machines come equipped with advanced features to handle the delicate carding process. The blow room machine process is the initial stage where raw cotton is prepared for carding, involving a series of machines that open, clean, and mix cotton fibers to form a uniform lap. Following this, the cotton carding stage aligns the fibers and removes any remaining impurities, resulting in a consistent and clean cotton sliver. This sliver is fundamental in spinning, where it is drawn out and twisted into yarn.

Materials and Techniques

In the carding process, different feeding techniques are employed to ensure a uniform thickness. For flat card machines, a consistent layer of cotton is fed through the use of opening and scutching machines. Conversely, roller-card machines utilize a weighing device that parcels out the fiber material at regular intervals, ensuring each batch is consistent in weight and quality. The choice of machine and technique directly impacts the uniformity and quality of the carded output.

Advantages of Modern Carding

Modern cotton carding machines offer a range of advantages. They are designed to be more efficient, reducing waste and increasing the quality of the carded fiber. With advancements in technology, these machines have become more user-friendly and require less manual intervention. The integration of automation within the carding process has led to higher throughput and better consistency in the quality of the cotton sliver, which is crucial for high-quality yarn production.

Choosing the Right Machine

Selecting the appropriate carding machine is vital for textile manufacturers. Factors such as the type of cotton, desired end-product, and production capacity play a significant role in this decision. While the cotton carding machine price is a consideration, the efficiency and output quality are often of paramount importance. Manufacturers may consult with cotton carding machine manufacturers to find a machine that aligns with their specific needs, ensuring an optimal carding process for their textile operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4