Understanding Compressed Air Receiver Tanks

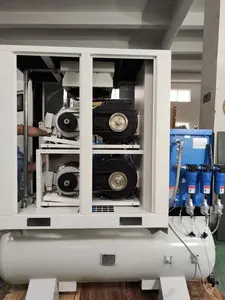

A compressed air receiver tank is an essential component in industrial pneumatic systems, serving as a reservoir of compressed air. This tank is crucial for smoothing out the pulsations from the air compressor and providing a steady flow of air to various tools and machinery. The role of these tanks is not just limited to storage but also to help in moisture separation and reducing the load on the compression system.

Types and Applications of Compressed Air Receivers

The versatility of compressed air receiver tanks is evident in their various types, such as vertical compressed air tanks and horizontal receivers. Each design is tailored to fit different space requirements and applications, ranging from small workshops to large industrial facilities. The industrial air compressor tank is a common sight in manufacturing plants, where it serves as a backbone for tools requiring high-pressure air. High pressure air receiver tanks are specifically designed to handle the demands of more intensive applications.

Features and Materials

The construction of a compressed air receiver involves robust materials like carbon steel to withstand high pressures. The internal coating and external finishing are designed to resist corrosion and extend the tank's lifespan. Features such as pressure gauges, safety valves, and drains are integral to the functionality and safety of these systems. A compressed air buffer tank may also include additional ports for sensors and connections, enhancing its utility in complex systems.

Advantages of Using Compressed Air Receivers

Incorporating a compressor receiver tank into a pneumatic system brings several advantages. It acts as a compressed air surge tank, mitigating the risk of pressure fluctuations that could potentially damage sensitive equipment. Moreover, it serves as a compressed air reservoir, ensuring that a steady supply of air is available for peak demand periods, thus optimizing the efficiency of the system.

Selecting the Right Compressed Air Receiver

When choosing a compressed air receiver tank, factors such as capacity, pressure rating, and size must be considered. For instance, a 500 gallon compressed air tank may be suitable for large-scale operations, while a smaller air receiver vessel might suffice for less demanding environments. It's also important to consider the space available; a large air receiver tank requires more floor space or may need to be installed outdoors.

Complementary Components for Compressed Air Systems

Beyond the tanks themselves, a complete compressed air system may include a receiver tank compressor, air compressor reservoir, and various other components such as filters and dryers to ensure the quality of the compressed air. For those looking to replace or upgrade their system, a used air receiver tank can be a cost-effective alternative, provided it meets the necessary safety and performance standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4