Exploring the Versatility of CNC Robots

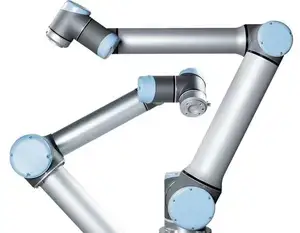

CNC robots represent a transformative leap in manufacturing and production technology. These sophisticated machines combine the precision of computer numerical control (CNC) with the flexibility of robotic arms, resulting in a cnc robot machine that can perform complex tasks with high efficiency. The integration of these systems into industrial processes has revolutionized the way objects are manipulated, shaped, and produced.

Types and Applications of CNC Robotics

The applications of cnc robots are diverse, ranging from robotic cnc machine operations to intricate robotic plasma cutting. In the realm of drilling, for instance, the fanuc robo drill exemplifies how these robots can be specialized for high-speed, precision tasks. Similarly, the kuka cnc milling robot showcases the adaptability of CNC robots in milling operations, capable of handling complex geometries with ease.

Features and Materials Handling

A key feature of CNC robots is their ability to handle a variety of materials with precision. Whether it's a cnc robotic milling machine shaping metal components or a hexapod cnc system working with composite materials, these robots are equipped to deal with a wide range of substances. This versatility extends to tasks such as cnc machine tending, where robots can load and unload CNC machines, maintaining a seamless production flow.

Advantages of Implementing CNC Robotics

The adoption of CNC robotics in manufacturing brings numerous advantages. These machines contribute to workplace safety by taking over tasks that are hazardous for human workers, thus reducing the incidence of workplace injuries. Moreover, the precision and repeatability of a cnc robot ensure high-quality production outcomes, while their ability to operate continuously enhances overall productivity.

Choosing the Right CNC Robot

Selecting the appropriate CNC robot for your operations involves considering several factors. The payload capacity is crucial, as each cnc robot machine is designed to handle a maximum weight limit. Additionally, the range of motion and the type of power source—be it electric, pneumatic, or hydraulic—are important considerations that affect the robot's performance in specific applications.

Training and Support for CNC Robot Operations

To fully leverage the capabilities of CNC robots, operators must be well-versed in their functions and maintenance. Resources such as fanuc cnc training, fanuc controls training, and fanuc cnc programming training are invaluable for teams to optimize the use of these machines. Furthermore, ongoing fanuc cnc maintenance training ensures that the robots continue to operate at peak efficiency.

For those interested in exploring the vast potential of CNC robotics, Alibaba.com offers a platform where a variety of CNC robots are available to meet the needs of different industries. While browsing the extensive selection, buyers can find the right machinery to enhance their production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4