What are CNC Milling Machines

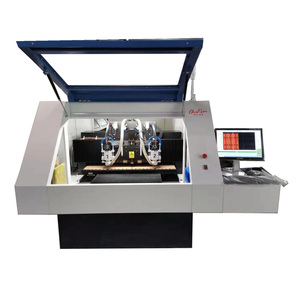

CNC milling machines are sophisticated pieces of equipment used in manufacturing to shape metal and other rigid materials through the use of computer-controlled, rotary cutting tools. CNC stands for Computer Numerical Control, reflecting the technology at the heart of these systems which allows for precise control of movement, speed, and machining processes. These machines are essential for businesses that require consistent quality and high precision in their products, such as those in the automotive, aerospace, and electronics industries, among many others.

The principle of CNC milling revolves around the subtractive manufacturing process—material is removed from a workpiece to create the desired shape or design. A typical CNC milling machine features a table that holds the workpiece in place while a spindle with the attached cutting tool moves across multiple axes. The movement can be linear or rotary, allowing for a wide range of cuts and shapes. The machine follows a pre-programmed path based on a digital design, ensuring repeatability and accuracy.

Operators input designs using specialized software which then translates these into machine-readable code. This code dictates every action of the milling machine, from the speed of the spindle to the depth of cut and cooling fluid delivery. The automation provided by CNC milling machines not only increases productivity but also reduces the possibility of human error, which is crucial for businesses that rely on precision engineering.

Types of CNC Milling Machines

CNC milling machines come in various configurations to suit different production needs. Some common types include:

Vertical Milling Machine: This type is characterized by a vertically oriented spindle that holds and rotates the cutting tool against the stationary workpiece. Vertical mills are versatile and commonly used for simpler jobs such as milling slots, drilling holes, or creating complex contours.

Horizontal Milling Machine: Featuring a horizontal spindle orientation, these machines are ideal for tasks requiring heavy material removal rates. They often come with multiple cutter heads to perform operations simultaneously, making them suitable for creating grooves or slots on large workpieces.

Universal Milling Machine: Offering flexibility in both horizontal and vertical milling capabilities, universal machines can handle a wide range of shapes and sizes. Their versatility makes them a good choice for shops that need to tackle different types of jobs.

Turret Milling Machine: Known for its stationary spindle and moving table design, turret mills offer precision and are good for detailed work on smaller parts. They're commonly found in tool rooms and smaller manufacturing facilities.

Bed-type Milling Machine: With a rigid bed design instead of a knee-and-column structure, these machines can handle larger loads. Their powerful cutting capabilities make them suitable for heavy-duty milling operations.

Each type has specific use cases depending on the industry's requirements, from simple tasks like drilling holes to complex operations like producing intricate aerospace components.

How to choose CNC Milling Machines

Selecting the right CNC milling machine involves understanding your business's specific needs and matching them with appropriate machine features. Consider these factors:

Machine Configuration: Evaluate whether vertical, horizontal, universal, turret, or bed-type configuration best suits your operations based on the parts you intend to produce.

Size and Power: Look at your typical workpiece size to determine the necessary table travel dimensions and assess the required power (spindle motor) for your material removal needs.

Control System: The CNC control system should be user-friendly and compatible with your CAM software to ensure seamless operation. Options like GSK, KND, Mitsubishi, Fanuc, Siemens, etc., are available.

Precision: Depending on how exact your cuts need to be, look at positioning accuracy specs like 0.005mm or 0.001mm to ensure your chosen machine can meet your tolerances.

Spindle Taper: Match the spindle taper (BT40, BT30) with your tooling requirements to ensure compatibility with existing tools or industry standards.

Drive Motor Type: Deciding between stepper or servo motors will affect your machine's precision and speed capabilities.

When focusing on B2B sales where volume purchases may be common, consider machinery that offers key selling points such as high productivity or multifunctionality to appeal to businesses aiming to maximize their investment return.

Best CNC Milling Machines on Alibaba.com

For businesses seeking reliable CNC milling solutions, Alibaba.com stands out as a global marketplace connecting buyers with suppliers offering a wide array of machinery tailored to diverse industrial needs. The platform's vast selection ranges from basic models perfect for small-scale operations to advanced machines designed for heavy-duty manufacturing. This variety ensures that every business can find equipment that aligns with its production demands and budget constraints.

Alibaba.com understands that purchasing decisions in the B2B sector involve significant investments; therefore, it prioritizes features like comprehensive after-sales services including online support and video technical assistance. Furthermore, Trade Assurance service acts as a safeguard ensuring payment protection until delivery fulfillment. This commitment to reliability fosters trust among buyers worldwide who utilize Alibaba.com for sourcing equipment capable of elevating their manufacturing processes.

The ease-of-use offered by Alibaba.com's mobile-friendly interface enables buyers to navigate product options effortlessly while accessing valuable information like machinery test reports and core component details such as motors and PLCs. With multilingual communication support and delivery services spanning over 190 countries and areas, Alibaba.com empowers businesses regardless of geographic location to access premium CNC milling machines suited for their specific industrial applications.

Common FAQs for CNC Milling Machines

What is a CNC milling machine used for?

CNC milling machines are used to manufacture complex parts through a subtractive process, which involves removing material from a solid block to achieve the desired shape or finish.

How does a CNC milling machine differ from a CNC lathe?

A CNC milling machine typically performs cutting operations using a rotating tool against a stationary workpiece, while a CNC lathe rotates the workpiece against a fixed cutting tool.

What materials can be machined with CNC milling machines?

CNC milling machines can machine a wide range of materials including metals, plastics, composites, and wood, depending on the machine's power and capabilities.

Can CNC milling machines produce parts with high precision?

Yes, CNC milling machines are capable of producing parts with high precision, often to tolerances of 0.005mm or better, depending on the machine's specifications.

What factors should I consider when choosing a CNC milling machine?

Consider factors such as the size and complexity of the parts you intend to produce, the precision required, the type of materials you'll be working with, and the volume of production.

How do I ensure compatibility between my tooling and the CNC milling machine?

Check the spindle taper specification of the CNC milling machine (e.g., BT40, BT30) to ensure it matches your existing tooling or select tooling that is compatible with your machine's spindle.

What are the benefits of using a vertical CNC milling machine?

Vertical CNC milling machines are versatile and can perform a wide range of tasks like drilling and slotting. They're typically easier to set up for small batch production and intricate parts.

What is the advantage of having multiple spindles in a CNC milling machine?

Multiple spindles can increase productivity by enabling simultaneous machining operations on either one large workpiece or multiple smaller pieces.

How important is the control system in a CNC milling machine?

The control system is crucial as it dictates the performance, capabilities, and ease of use of the CNC milling machine. A user-friendly interface and compatibility with your CAM software are essential for efficient operation.

What after-sales services should I expect with my CNC milling machine purchase?

After-sales services may include online support, video technical support, and field maintenance. The availability of engineers for overseas service or local service centers can also be important considerations.

What does 'machining capacity' mean in terms of CNC milling machines?

Machining capacity refers to the ability of the machine to handle tasks ranging from light-duty (smaller parts and softer materials) to heavy-duty (large parts and tougher materials) machining requirements.

How does table travel affect my choice in a CNC milling machine?

Table travel dimensions determine the maximum size of workpiece you can machine. Ensure that the X (length) and Y (width) axes travel meet or exceed the size of your largest workpieces.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4