Understanding Cloth Inspection Machines

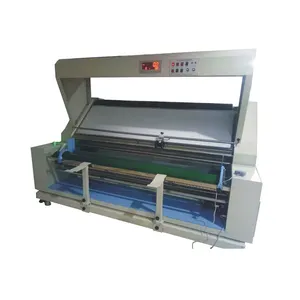

The textile industry relies heavily on precision and quality control, making the cloth inspection machine an indispensable asset. This category encompasses a range of equipment designed to scrutinize fabrics for flaws and ensure consistency in texture, color, and pattern. The importance of this machinery lies in its ability to detect imperfections post-production, a critical step before the fabric reaches the market.

Types and Features of Fabric Inspection Systems

Fabric inspection systems vary widely to accommodate different materials and production scales. From simple manual inspection tables to sophisticated automated systems, each textile measuring machine is tailored to specific industry needs. Advanced models may include high-resolution cameras and sensors that meticulously analyze fabric as it moves through the production line, ensuring every inch is examined for quality.

Applications Across Textile Production

The scope of a textile inspection machine extends beyond mere examination. It plays a pivotal role in assessing a fabric's weight, width, and stretchability, which are crucial for applications ranging from apparel to industrial textiles. The adaptability of these machines allows for their use with a variety of fabrics, from lightweight silks to heavy denims, making them a versatile tool in the textile industry.

Material Handling and Machine Variants

Material handling is a significant factor when selecting a fabric quality control machine. Options include clip and pin stenters, each suited to different fabric weights and types. Clip stenters are typically preferred for heavier materials, providing a firm grip without damaging the fabric. Conversely, pin stenters are ideal for lighter, more delicate textiles. The choice of machine affects the efficiency and quality of the inspection process.

Advantages of Modern Inspection Equipment

Modern cloth quality inspection machines offer numerous advantages, such as increased speed and accuracy in defect detection. This not only enhances the quality of the final product but also streamlines the production process. With features like adjustable speed settings and multiple drying units, these machines can be customized to meet the throughput requirements of various textile operations.

Selecting the Right Machine on Alibaba.com

Alibaba.com hosts a comprehensive collection of cloth inspection solutions, catering to diverse business needs. The platform facilitates the selection of a suitable textile quality control machine without advocating for any specific brand or service. The emphasis is on connecting buyers with a range of options, allowing them to compare and choose based on their unique requirements. Alibaba.com's customer service team is available to assist with inquiries, ensuring a seamless procurement experience.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4