Introduction to Circular Knife Grinding Machines

Circular knife grinding machines are specialized pieces of equipment designed for the precise sharpening and reconditioning of circular knives. These machines are pivotal in various industries where sharp cutting tools are paramount to the production process. With a robust market presence, these machines cater to a diverse range of applications, from textile manufacturing to plastic processing.

Types and Applications

The versatility of circular knife grinding machines is reflected in the variety of models available, including but not limited to, other grinding machines, cylindrical grinders, and surface grinding machines. Each type serves a specific purpose, from reshaping the knife to achieving a fine finish. Common applications span across countries such as Thailand, Spain, and the United States, emphasizing the global demand for these precision tools.

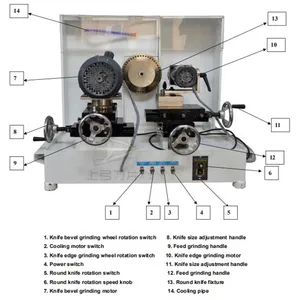

Features and Materials

A circular knife grinder is equipped with features that ensure efficient and accurate grinding. These include adjustable speed settings, precision components, and durable construction materials like high-grade steel and industrial-grade diamonds for the grinding wheels. The choice of material not only contributes to the machine's longevity but also to the quality of the sharpening process.

Advantages of Using a Circular Knife Grinder

The use of a blade sharpening machine offers numerous advantages. It enhances the lifespan of circular knives by maintaining their sharpness, which is crucial for industries that rely on cutting precision. Moreover, a well-maintained knife reduces material wastage and improves the efficiency of the cutting process.

Selection Criteria

When selecting a knife sharpening machine, factors such as the type of knives to be sharpened, the required precision level, and the volume of knives that need servicing should be considered. Additionally, features like gear, engine, and gearbox configurations may influence the machine's performance and suitability for specific environments like manufacturing plants, garment shops, or building material shops.

Technical Support and Services

While exploring options for a sharpener for circular knives, potential buyers should consider the technical support available, such as video technical support or online assistance. This support is crucial for troubleshooting and ensuring the machine operates at its optimal capacity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4