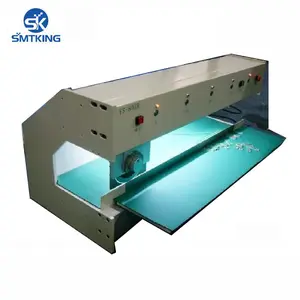

Introduction to Circuit Board Machines

Circuit board machines are integral components in the electronics manufacturing industry, facilitating the creation of various electronic components with precision and efficiency. These machines cater to different stages of production, from the initial PCB fabrication to the final assembly processes.

Types and Applications

Circuit board assembly machines are diverse, each tailored to specific tasks within the electronic production line. Applications range from constructing electronic motherboards to assembling intricate devices like LED lights and cameras. The versatility of these machines allows for their use in producing a multitude of household electronic devices.

Automated Processes and Features

The automated nature of PCB machines ensures a rapid production rate, essential for meeting the demands of the fast-paced electronics market. These machines include units for PCB fabrication, cutting, printing, component placement, and soldering. Advanced soldering machines feature flux systems that clean and prepare metals for soldering while preventing oxidation. Additionally, transport systems within these machines are designed to handle PCBs of varying sizes, enhancing the adaptability of the production process.

Control and Precision

A sophisticated control interface is a hallmark of a quality circuit board machine, allowing operators to fine-tune settings such as soldering temperature and conveyor speed. This level of control is crucial for maintaining the precision required in electronic manufacturing. Moreover, pick and place machines demonstrate impressive capabilities, with some models placing thousands of microchips per hour.

Customization and Adaptability

The adaptability of PCB assembly equipment is evident in the customizable features like adjustable soldering units, heating, and cooling systems. These machines are designed to accommodate different PCB sizes and are equipped with nitrogen protection and performance testing systems to ensure the integrity of the electronic components produced.

Choosing the Right Machine

Selecting the appropriate circuit board machine involves considering factors such as capabilities, size, and weight. Prospective buyers are encouraged to assess their production needs to identify the machine that aligns with their operational requirements. Alibaba.com hosts a comprehensive selection of these machines, offering a platform for buyers to connect with suppliers and find equipment that meets their specific manufacturing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4