Introduction to Spot Welders

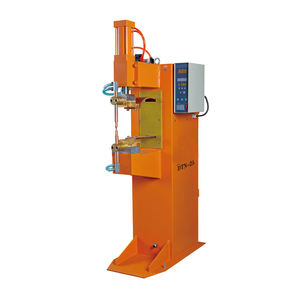

Spot welding stands as a versatile and efficient process used in various manufacturing sectors. An inexpensive spot welder is a pivotal tool for businesses requiring effective metal joining solutions. This category encompasses a range of devices designed to cater to different welding needs, including spot, projection, and seam welding.

Types and Applications

The application of affordable spot welders extends across industries, from automotive to construction. These machines facilitate the joining of sheet metal and other materials with precision and strength. Users can select from a variety of welding technologies, such as stick or gas welding, each suitable for specific tasks and environments.

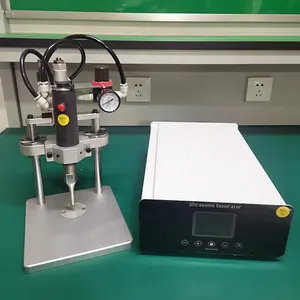

Features and Materials

Cost-effective spot welders are engineered with user-friendly features to enhance the welding experience. They are typically compact and lightweight, promoting portability for both indoor and outdoor projects. With functionalities like hot start and arc force, these welders are designed to accommodate a broad range of welding requirements. The construction of these machines often involves durable materials that withstand the rigors of welding tasks while ensuring longevity.

Advantages of Using Spot Welders

Utilizing a budget-friendly spot welder offers numerous advantages. These machines are known for their ease of use and the ability to produce strong welds quickly. With built-in protection against overheating and voltage fluctuations, they provide a reliable solution for continuous welding operations. The adaptability of these welders to various metals and thicknesses makes them an indispensable tool for many businesses.

Considerations for Selection

When selecting a value spot welder, it is important to consider the primary voltage requirements and the power capacity, which directly influence the machine's capability to weld different material thicknesses. While a 230v system may suffice for portable units, more intensive welding tasks may necessitate a 400v system. The choice of welder should align with the specific needs of the task at hand.

Complementary Welding Equipment

In addition to economical spot welders, a comprehensive selection of related welding equipment, accessories, and tools is available to complement your welding projects. It is essential to review and understand the instructions for each piece of equipment to ensure safe and effective operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4