Understanding Centrifugal Gas Compressors

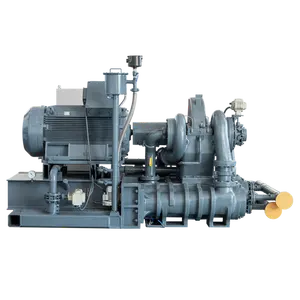

A centrifugal gas compressor is a pivotal piece of equipment in various industrial sectors, transforming kinetic energy into pressurized air. This pressurized air is then utilized to power an array of industrial machinery, making the compressor a cornerstone in operations ranging from agriculture to manufacturing. The working principle of these compressors involves radial acceleration and conversion of incoming gas into high-velocity fluid, which is then decelerated to increase pressure.

Types and Applications

The versatility of centrifugal gas compressors is evident in their wide range of applications. From the centrifugal compressor in gas turbines to their role in the oil and gas industry, these compressors are integral. Industries benefit from various types, such as the siemens centrifugal compressors known for their reliability, or the atlas copco integrally geared compressor, renowned for its energy efficiency. The hydrogen centrifugal compressor is particularly noteworthy for its use in renewable energy sectors, highlighting the adaptability of these machines.

Features and Materials

Centrifugal compressors are designed with durability and efficiency in mind. Materials used in construction, such as high-grade alloys, ensure longevity and resilience. The api 617 compressor standard, for instance, specifies materials and design criteria for high-performance in demanding environments. Additionally, the centrifugal compressor oil and gas variants are tailored to handle the corrosive and abrasive nature of hydrocarbon processing.

Advantages of Centrifugal Compressors

The benefits of using a centrifugal gas compressor are manifold. They offer a continuous flow of pressurized gas, essential for seamless industrial operations. The gas turbine driven centrifugal compressor and steam turbine driven centrifugal compressor are examples of units that provide high efficiency and reliability. Furthermore, the centrifugal hydrogen compressor represents a leap forward in supporting cleaner energy applications, underscoring the compressor's role in sustainable industrial practices.

Design and Mobility

In terms of design, centrifugal compressors are engineered to meet the specific needs of various industries. Some models are designed for stationary use within factories, while others, like the natural gas centrifugal compressor, are built for on-site applications with features such as trailer attachments for easy transportation. The focus on mobility and reduced noise levels is crucial for on-site operations, particularly in construction and field services.

Choosing the Right Compressor

Selecting the appropriate centrifugal gas compressor requires an understanding of the specific industrial needs and the operational context. Factors such as power rating, intended application, and material compatibility are critical considerations. While the platform provides a diverse catalog, it is essential for buyers to assess the specifications and features of each model, such as those adhering to compressor api 617 standards, to ensure the right fit for their industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4