Candle Making Equipment: An Overview

The craft of candle making has evolved significantly with the advent of modern candle making equipment. This category encompasses a diverse range of tools and machinery designed to streamline the production of candles, whether for artisanal boutiques or larger manufacturing plants. The equipment varies from wax melting systems to automated candle molding machines, each serving a specific function in the candle creation process.

Types of Candle Making Equipment

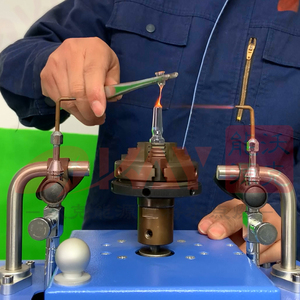

Within the realm of candle production, various types of equipment are utilized to cater to different stages of manufacturing. Wax & candle making machines form the backbone of the industry, providing efficient means to melt and mold wax. Other essential tools include wick-cutting machines, dipping tanks for taper candles, and rolling machines for beeswax candles. The choice of equipment often depends on the scale of production and the type of candles being produced.

Materials and Features

The construction of candle making machinery typically involves robust materials such as stainless steel, ensuring durability and ease of maintenance. Innovations in the field have led to the integration of temperature control systems and automated pouring for precision and consistency in candle production. Additionally, the use of eco-friendly materials like soy wax and paraffin wax in the equipment design caters to the growing demand for sustainable production practices.

Applications and Versatility

Candle making equipment is versatile, finding applications across various settings including boutique workshops, hotels, and large-scale manufacturing plants. The adaptability of the equipment allows for the production of a myriad of candle types, from simple tea lights to intricate aromatic candles, meeting the diverse needs of the market.

Advantages of Modern Equipment

The integration of modern candle making tools into the production process offers numerous advantages. Efficiency is significantly enhanced, with machines capable of producing large batches of candles in a fraction of the time it would take manually. This equipment also ensures uniformity in product quality, which is crucial for brand reputation and customer satisfaction. Moreover, the automation of repetitive tasks reduces labor costs and the potential for human error.

Choosing the Right Equipment

Selecting the appropriate candle making supplies is crucial for any business in this industry. Factors to consider include the type of candles being produced, the scale of operations, and the specific features required for certain candle designs. While the market offers a wide array of options, it is essential to assess the compatibility of the equipment with the intended production goals to ensure optimal functionality and efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4