Introduction to Brush Tufting Machines

The realm of brush manufacturing is revolutionized by the advent of brush tufting machines, a cornerstone in the production of various brush types. These machines serve as the backbone for businesses looking to enhance their brush production efficiency. A brush tufting machine is designed to insert bristles into the brush base precisely, catering to a range of brush designs and functions.

Variety and Specifications

Diversity in design and functionality is evident in the array of brush tufting machines available. From compact models suitable for small-scale operations to larger, industrial-grade machines that cater to high-volume production, the selection is tailored to meet different operational scales and requirements. Each machine varies in aspects such as speed, bristle type compatibility, and tufting patterns, allowing for a tailored approach to brush production.

Operational Efficiency

Efficiency is a hallmark of these machines, with a focus on reducing both time and labor inputs. The operational design of a brush tufting machine emphasizes ease of use, with straightforward maintenance and cleaning processes. This operational efficiency is not only a time-saver but also contributes to the overall cost-effectiveness of the production process.

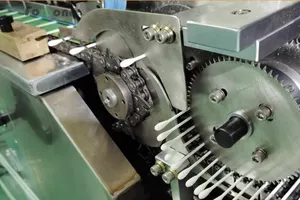

Durability and Performance

Constructed from durable materials, brush tufting machines are built to withstand the rigors of production environments. Resistance to mechanical impacts, corrosion, and humidity is a testament to their longevity. This robust construction ensures consistent performance, which is crucial for maintaining production standards.

Safety and Sustainability

Safety is paramount in the design of brush tufting machines, with features integrated to minimize the risk of operator injury. Additionally, these machines align with sustainability goals through their low energy consumption. The materials used in the construction of these machines are selected for their recyclability, further reducing the environmental footprint of brush production.

Choosing the Right Machine

Selecting the appropriate brush tufting machine involves considering both financial and productivity objectives. The range of machines available ensures that there is a fit for every production need without compromising on efficiency or output quality. When exploring options, it is essential to evaluate the machine's compatibility with the intended brush production specifications and the scale of operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4