Banana Processing Plant Overview

The banana processing plant is a comprehensive setup designed for transforming bananas into various value-added products. This facility encompasses a range of machinery and equipment tailored to modify the fruit from its natural state into forms that are more suitable for consumption, storage, and transportation. The scope of these plants can vary significantly, from small-scale units to large, commercial-scale operations.

Types of Banana Processing Machinery

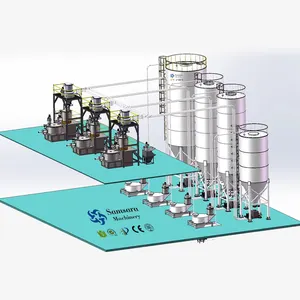

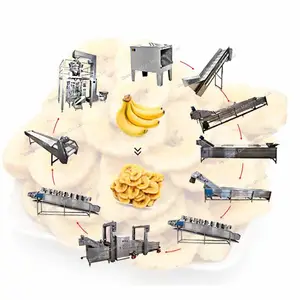

Within a typical banana processing unit, one might find an array of specialized machinery. This includes the plantain chips making machine, which is engineered for slicing bananas into thin chips before they are fried and packaged. Another essential piece of equipment is the banana powder processing plant, which dehydrates bananas to produce banana powder, a versatile ingredient in the food industry. Additionally, the banana ripening plant plays a crucial role in controlling the ripening process to ensure bananas reach consumers at the perfect stage of maturity.

Applications and Features

The applications of a banana processing plant are diverse. For instance, the commercial plantain chips production line is pivotal in the snack industry, providing a systematic approach to producing plantain chips at a commercial scale. Similarly, the plantain flour making machine is instrumental in the production of gluten-free flour, catering to a growing market of health-conscious consumers. These machines are designed for efficiency, with features that aim to enhance productivity, such as automated slicing and drying systems.

Materials and Advantages

Materials used in the construction of banana processing machinery are selected for durability and food safety. Stainless steel is commonly used for its resistance to corrosion and ease of cleaning. The advantages of investing in a banana processing plant include the potential for increased productivity, the ability to meet large orders, and the diversification of banana-based products.

Considerations for Purchasing

When considering the acquisition of a banana processing plant cost is a significant factor, but it should be weighed against the efficiency and output of the plant. Size is another important consideration, as the machinery must fit within the allocated production space. For businesses with space constraints, opting for a machine for cutting plantain chips that is modular can be a space-saving solution without compromising on functionality.

Maximizing Production

To maximize production, it is essential to select a banana processing plant that aligns with the specific needs of your operation. This includes considering the types of banana products you intend to produce, such as plantain chips or banana powder, and ensuring the machinery is capable of delivering the desired output. Efficiency in production not only saves time but may also lead to a better return on investment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4