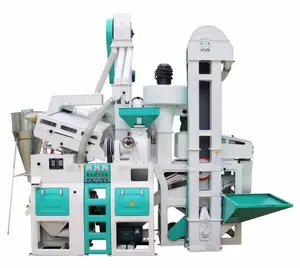

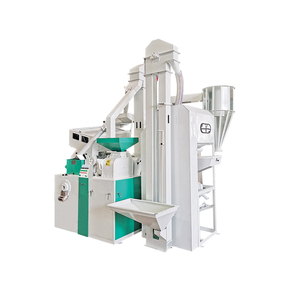

Introduction to Automatic Rice Mill Plants

The automatic rice mill plant is a comprehensive setup designed to facilitate the processing of rice from its raw, paddy form into the finished, polished grain. This sophisticated machinery embodies efficiency and technological advancement in the agricultural sector. It is a pivotal tool for businesses looking to streamline their rice milling operations.

Operational Considerations

To ensure the seamless operation of an automatic rice mill plant, it is crucial for operators to conduct regular maintenance checks. This includes verifying the condition of the transmission belt and ensuring that all moving parts are well-lubricated for optimal performance. Additionally, the removal of contaminants such as stones and iron from the rice is essential to prevent damage to the milling machinery and to maintain the integrity of the milling process.

Factors to Consider When Selecting a Rice Milling Plant

Selecting the right automatic rice mill plant requires careful consideration of several factors. The space available for installation is a primary concern, as the plant should not only fit within the designated area but also allow for operational maneuverability. The capacity of the plant is another significant aspect, with larger scale operations necessitating more robust machinery. Furthermore, the availability of spare parts is a practical consideration, given the wear and tear on components such as the rice huller screen and the whitening cylinder.

Features and Advantages of Rice Milling Plants

An automatic rice mill plant is equipped with features that promote efficiency and ease of use. For instance, the automation of the milling process reduces the need for constant manual supervision, allowing for a more streamlined workflow. The advantages of using such a plant include consistent product quality, reduced labor costs, and a faster turnaround time from paddy to polished rice.

Materials and Durability

The construction of an automatic rice mill plant involves durable materials capable of withstanding the rigors of rice processing. The use of industrial-grade metals ensures longevity and resistance to the stress caused by continuous operation. Regular replacement of consumable parts is necessary to maintain the efficiency and longevity of the plant.

Choosing the Right Rice Milling Solution on Alibaba.com

Alibaba.com offers a diverse array of automatic rice mill plants to meet the needs of various business scales and requirements. The platform connects buyers with a network of wholesalers, providing a multitude of options without advocating for any single brand or price point. Prospective buyers can explore the extensive listings to find a plant that aligns with their operational needs and budgetary constraints.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4