Introduction to Aluminum Die Casting Machines

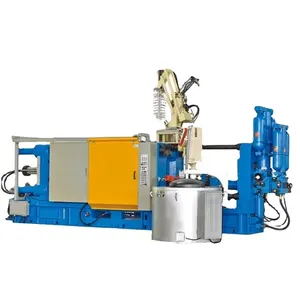

Aluminum die casting machines are pivotal in the manufacturing sector, serving as the backbone for producing intricate aluminum parts with high precision. These machines facilitate the production of components by injecting molten aluminum into a mold at high pressure, a process central to industries requiring metal parts with excellent dimensional accuracy.

Types and Applications

The variety of aluminium die casting machines includes both hot chamber and cold chamber machines, each suited for specific applications. Hot chamber machines are typically used for metals with low melting points, while cold chamber machines are suitable for aluminum due to its higher melting temperature. These machines are instrumental in automotive, aerospace, and electronics industries, where the integrity and strength of components are paramount.

Features and Materials

Modern aluminium casting machines are engineered with advanced features to ensure efficient and consistent production. They are constructed using robust materials that withstand the stresses of die casting, including the intense heat and pressure involved in the process. The durability of these machines is a testament to the rigorous standards adhered to by aluminium die casting machine manufacturers.

Advantages of Using Quality Die Casting Machines

The use of a high-grade aluminium pressure die casting machine brings numerous advantages. Their precision in casting reduces waste and the need for secondary machining, while their speed enhances production rates. The reliability of these machines minimizes downtime, and when paired with the availability of spares, such as those for a used aluminium pressure die casting machine, ensures continuous operation.

Practicality and Versatility

The practicality of an aluminium casting machine lies in its versatility. Capable of producing a wide range of shapes and sizes, these machines can be adjusted to meet the specific requirements of various products. This flexibility makes them a valuable asset for businesses looking to diversify their offerings or tailor their production to niche markets.

Ensuring Operator Safety

Safety is a critical aspect of die casting operations. Aluminium pressure die casting machines are equipped with safety features that protect operators from work-related injuries, ensuring a safe working environment. The design of these machines often includes protective barriers, emergency stop functions, and other safety measures to mitigate risks.

In conclusion, the selection of an aluminum die casting machine can significantly influence the efficiency and quality of production. With a range of models tailored to various industry needs, these machines are a cornerstone for businesses aiming to excel in precision manufacturing. While Alibaba.com serves as a marketplace to connect buyers with a plethora of suppliers, it is essential to consider the specific requirements and capabilities of the aluminum die casting machinery to ensure the best fit for your manufacturing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4